ShinEtsu G-776 – Reliable Thermal Grease With Low Pump-Out

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

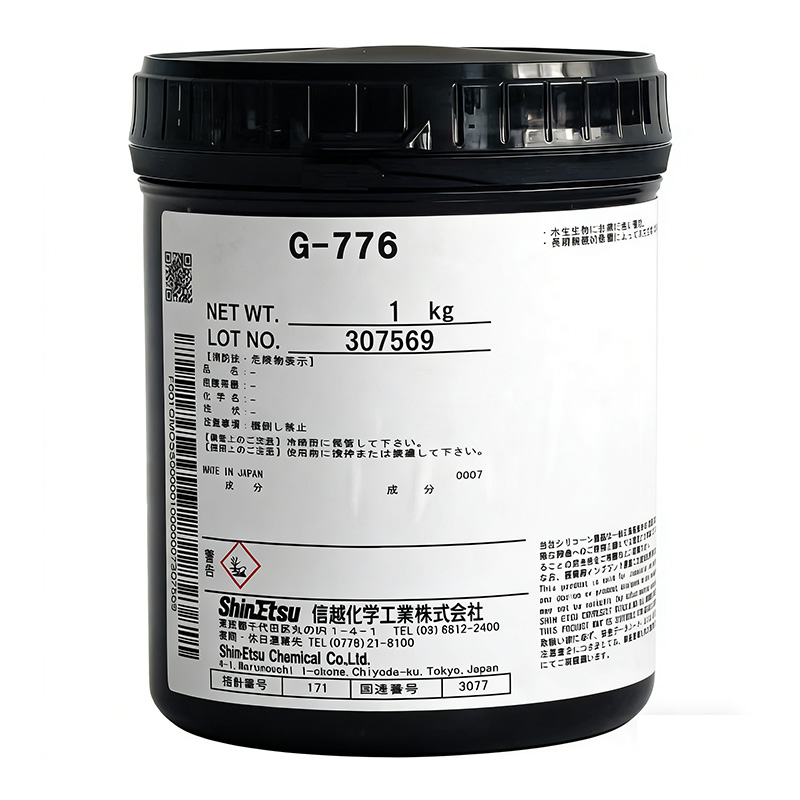

ShinEtsu G-776 is a silicone-based thermal interface grease developed for stable and repeatable heat transfer in high-reliability electronic assemblies. As an authorized distributor of Shin-Etsu products with in-house formulation and development capabilities, we supply original materials while also supporting customized thermal interface solutions tailored to specific assembly structures, operating temperatures, and long-term reliability requirements. In practical use, G-776 delivers consistent application behavior, predictable spread under mounting pressure, and stable thermal performance throughout repeated thermal cycles, supporting controlled assembly processes and dependable device operation. This makes it ideal for CPUs, MPUs, and power devices requiring long-term cooling efficiency.

Products parameters

| Composition: | Silicone Thermal Grease (TIM) |

| Appearance: | White To Gray Paste |

| Viscosity 25 °C mm²/s: | ~1,200 |

| Specific Gravity At 25 °C: | ~2.50 |

| Refractive Index At 25 °C | ~1.420 |

| Packaging: | 1KG |

Key features

Thermal Conductivity - ShinEtsu G-776 is engineered as a silicone thermal grease TIM with optimized filler dispersion to support stable heat transfer across contact interfaces. At a working viscosity of approximately 1,200 mm²/s at 25 °C, the material spreads uniformly under mounting pressure, maintaining continuous contact between heat sources and heat sinks. This flow behavior supports consistent thermal resistance performance across large contact areas without localized dry zones during operation.

Low Pump-Out - The formulation exhibits strong resistance to mechanical displacement under thermal cycling conditions. With a specific gravity of approximately 2.50 at 25 °C, the material maintains structural stability and adhesion at the interface during repeated expansion and contraction. This property reduces grease migration from the contact zone, supporting long-term thermal efficiency in devices exposed to continuous on-off or load-fluctuation cycles.

Thermal Stability - G-776 maintains physical consistency and performance across elevated operating temperatures commonly found in power electronics. The silicone matrix resists viscosity drift during prolonged thermal exposure, supporting stable interface thickness during sustained heat generation. This stability supports predictable cooling performance throughout extended service life in high-power electronic assemblies.

Interface Adhesion - The grease provides controlled surface wetting and adhesion to metal heat spreaders and semiconductor packages. With a refractive index of approximately 1.420 at 25 °C, the material demonstrates uniform filler dispersion and interface contact quality. This adhesion behavior supports reduced interfacial air gaps and stable thermal contact during long-term device operation.

CPUs and MPUs - ShinEtsu G-776 is applied between processors and heat sinks to support stable heat dissipation under high computational loads. Its controlled viscosity supports uniform spreading during mounting, while pump-out resistance maintains interface integrity across repeated thermal cycling. This supports consistent processor operating temperatures in high-performance computing environments.

Power Transistors - In power semiconductor assemblies, G-776 supports efficient heat transfer from transistor packages to cooling components. The material maintains stable contact pressure distribution, reducing thermal resistance variations during load changes. This contributes to predictable thermal behavior in power conversion and control systems.

Heat Sink Interfaces - The grease is used in thermal interfaces between metal heat sinks and electronic modules where surface flatness variations exist. Its flow characteristics allow it to fill micro-level surface irregularities without excessive squeeze-out. This supports stable thermal pathways in compact electronic enclosures.

Telecom Equipment - G-776 is used in telecommunications hardware requiring continuous thermal management under long operational cycles. The material maintains consistent interface performance during sustained operation and environmental temperature variation. This supports long-term reliability in network infrastructure and communication modules.