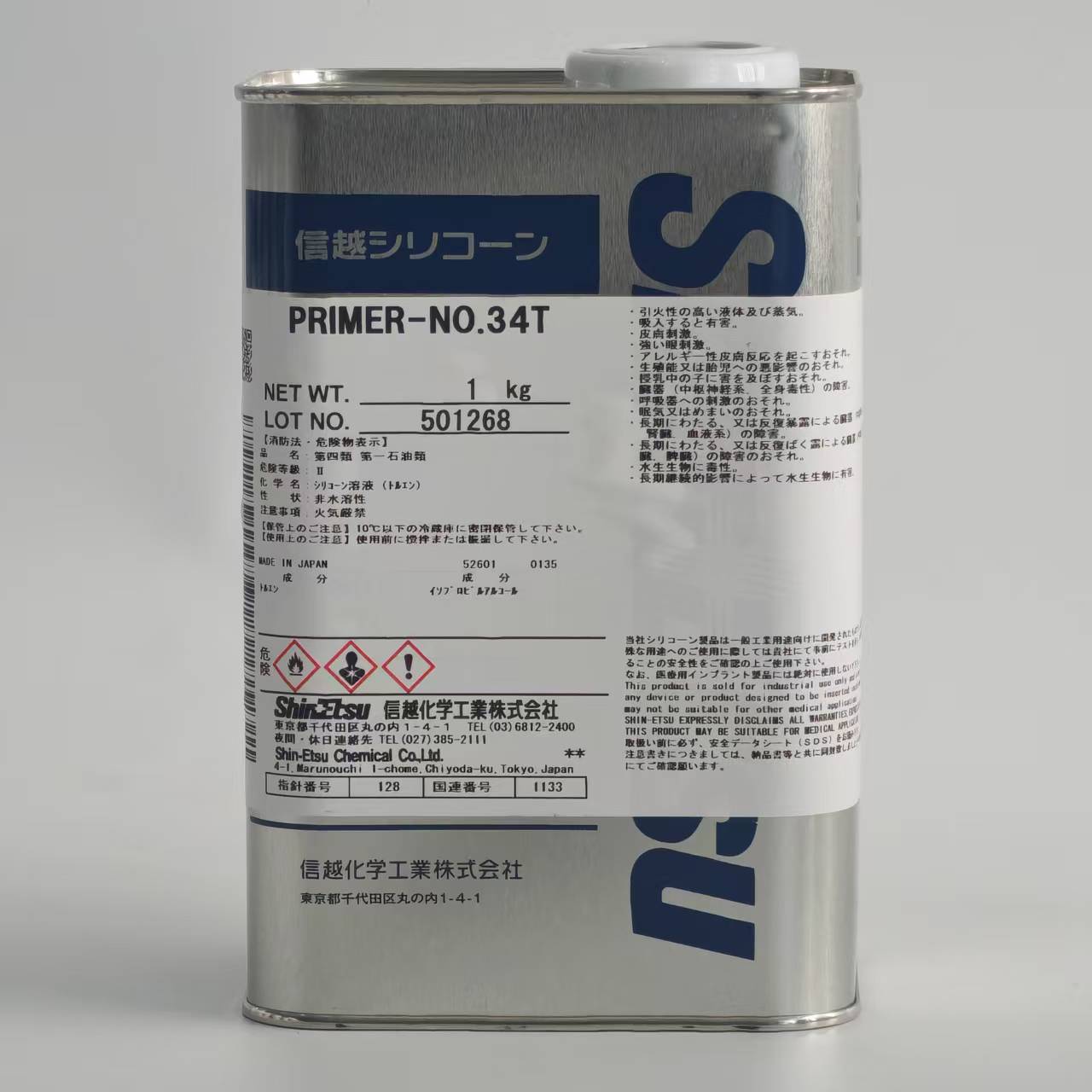

ShinEtsu PRIMER No.34T - Adhesion Promoter for Silicone Rubber, Coatings, And Sealants

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

PRIMER No. 34T is a silicone-modified primer designed to enhance the bonding between silicone rubber and metal substrates. It is a milky white, translucent liquid that cures at room temperature, with accelerated curing at elevated temperatures, offering excellent operational flexibility. This product effectively strengthens the bond between silicone rubber and metal, significantly improving interfacial stability and preventing delamination or cracking. Therefore, it is ideal for rubber-to-metal sealing, molding, and coating applications.

products parameters

| Appearance: | Milky White Translucent Liquid |

| Hardening Standard: | 25°C × 10-30min +150°C × 10-30min |

| Packaging: | 1kg |

key features

Solvent-Free Design - PRIMER No. 34T contains no organic solvents, reducing VOC emissions and complying with environmental regulations. Tests show that the concentration of organic solvents in air after application is less than 5 ppm, well below the limits in most countries.

Room-Temperature Curing - This primer completes initial curing in 10 to 30 minutes at 25°C, eliminating the need for additional heating equipment. Process testing has shown that its curing efficiency exceeds 95% at room temperature, with bond strengths consistently exceeding 7 MPa.

Excellent Adhesion - PRIMER No. 34T forms a strong bond on a variety of metals and silicone rubber surfaces. Test data shows peel strengths exceeding 6 N/mm on aluminum and over 7 N/mm on stainless steel. It maintains a stable bond on both rough and smooth surfaces.

Enhanced Adhesion of Adhesives and Paints - Experiments have shown that PRIMER No. 34T improves the overall adhesion of adhesives and paints when used as a primer. After a 30-minute high-temperature curing test at 150°C, the adhesive peel strength increased by 20% and the coating layer's impact strength increased by 15%. This makes it a key component in a variety of coating systems.

Wide Temperature Resistance - This product maintains stable bonding performance in environments ranging from -40°C to +150°C. Thermal cycling tests show that after 100 temperature cycles, bond strength retention remains above 90%. This ensures reliability in extreme environments, making it particularly suitable for industrial applications subject to frequent high and low-temperature cycles.

Automotive Industry - In automotive parts manufacturing, PRIMER No. 34T is widely used for bonding silicone rubber to metal. Tests have shown that applying this primer reduces the debonding rate of automotive seals by 25% over long-term use, significantly improving seal reliability. It can withstand both high engine compartment temperatures and low ambient temperatures.

Electronics Industry - During the encapsulation and insulation process of electronic components, this primer ensures a strong bond between silicone rubber and metal conductors or housings. Testing has shown that bond strength stability is improved by over 30% under high-humidity and high-temperature testing conditions for electronic products. This effectively prevents insulation failure caused by moisture intrusion.

Construction Industry - In building sealants and waterproof coatings, PRIMER No. 34T can be used to enhance the bond strength between silicone rubber and metal frames. Engineering test data shows that its use in exterior wall sealing strips has extended the bond life by over five years, effectively resisting damage caused by wind, rain, temperature fluctuations, and UV rays.

Molding Manufacturing - In rubber and metal molding processes, this primer significantly reduces interfacial debonding after demolding. Statistics show that the use of PRIMER No. 34T increases the qualified rate of molded products by 12% and reduces the rework rate by more than 20%. This significantly improves production efficiency and quality consistency.