ShinEtsu KR-255 - Silicone Resin for Coating & Moisture Proofing

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

ShinEtsu KR-255 Silicone Resin is a methyl and phenyl modified silicone resin designed for use as a coating-grade material that delivers a stable and controlled user experience during application and curing. In practical use, it presents as a transparent liquid that spreads evenly, levels smoothly, and forms a continuous film after curing, providing a clean and consistent coating surface. Its balanced handling characteristics support stable coating operations where appearance consistency, film integrity, and long-term reliability are required.

Products parameters

| Composition: | Silicone Resin |

| Appearance: | Colorless To Pale Brown Transparent Liquid |

| Visocity At 25°C: | 85mm^2/s |

| Specfic Gravity: | 1.02 |

| Curing Method: | Heat Curing,Room Temperature Drying |

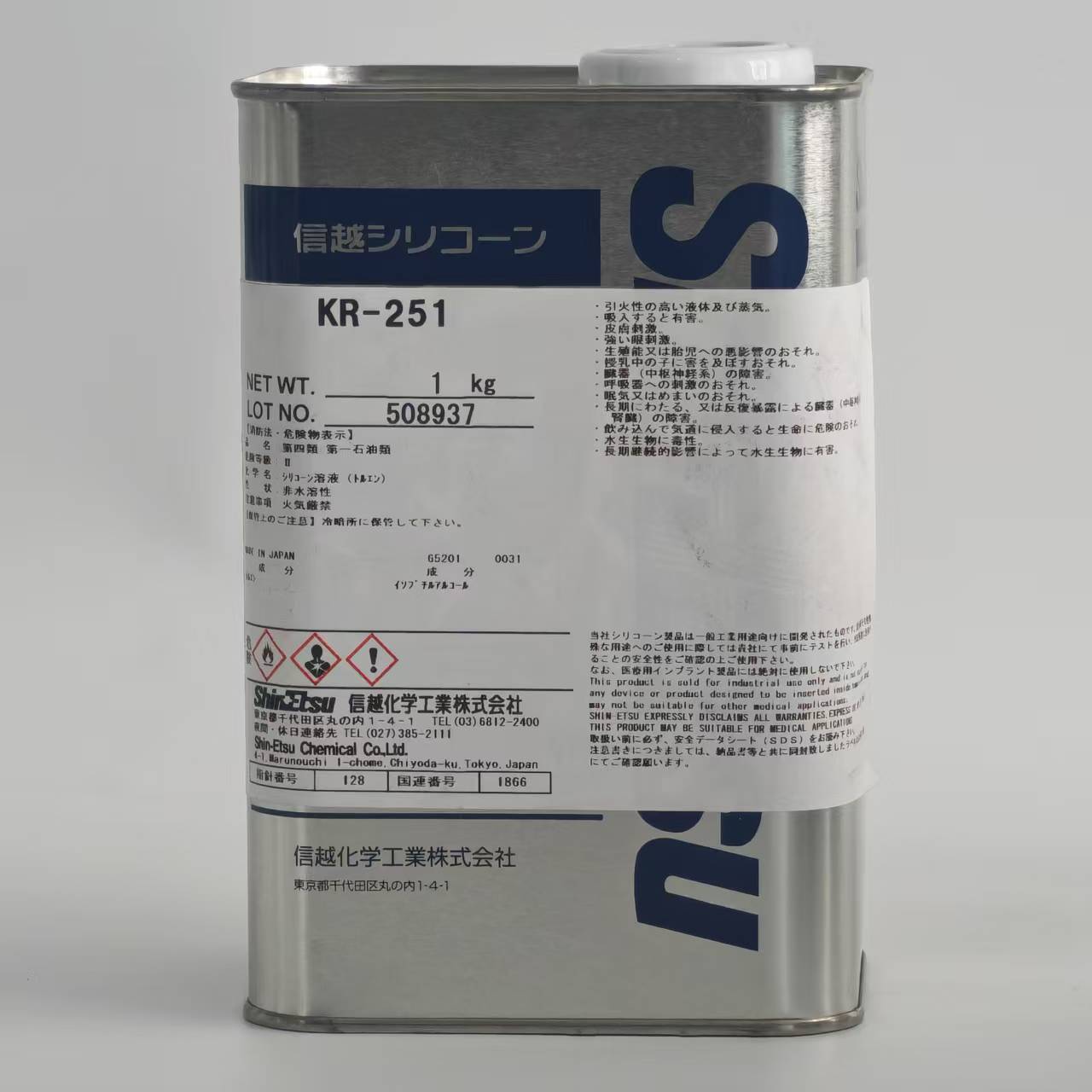

| Packaging: | 1kg |

Key features

Water Resistance - ShinEtsu KR-255 forms a cured silicone resin film with strong water repellency due to its methyl-rich molecular structure. Standard water immersion testing shows minimal water uptake, with film integrity maintained after prolonged exposure to moisture. This behavior supports stable coating performance in humid environments while preventing moisture penetration that could compromise surface protection.

Electrical Insulation - The cured resin exhibits high dielectric strength and low electrical conductivity, making it suitable for insulating coatings. Typical silicone resin films demonstrate dielectric strength above 20 kV per millimeter and volume resistivity exceeding 10¹⁴ ohm·cm. These values support reliable electrical isolation while maintaining stable insulating performance under continuous electrical load.

Weather Resistance - ShinEtsu KR-255 shows strong resistance to ultraviolet radiation, ozone, and atmospheric oxidation. Accelerated weathering tests indicate limited yellowing, cracking, or chalking after extended UV exposure. This stability ensures long-term film durability in outdoor or semi-exposed environments without loss of transparency or surface integrity.

Heat Resistance - The silicone-oxygen backbone of KR-255 allows continuous thermal resistance in the range of 200 to 300°C, with short-term tolerance at higher temperatures. Thermal aging data confirms that cured films retain structural stability and adhesion without decomposition, supporting use in environments with sustained heat exposure.

Chemical Stability - The cured resin demonstrates resistance to acids, bases, and a wide range of common solvents. Chemical immersion tests show minimal swelling or degradation when exposed to chemically aggressive media, allowing the coating to maintain protective performance and surface continuity under chemically demanding conditions.

Electronics Insulation - ShinEtsu KR-255 Silicone Resin is used as an insulating coating in electronic components where stable dielectric performance and moisture protection are required. The cured film supports consistent electrical isolation while maintaining transparency and adhesion, helping protect sensitive circuitry from environmental exposure and electrical leakage.

Manufacturing Coatings - In manufacturing environments, the resin is applied as a protective and functional coating on components requiring surface hardness and environmental resistance. Its moderate curing speed and stable viscosity allow controlled coating thickness, supporting consistent production quality across large-scale coating processes.

Coating Industry - Within the coating industry, KR-255 serves as a base silicone resin for formulations targeting durability and long service life. Its balanced flow behavior and curing characteristics enable reliable film formation, supporting coating systems that require long-term resistance to weathering, heat, and chemical exposure.