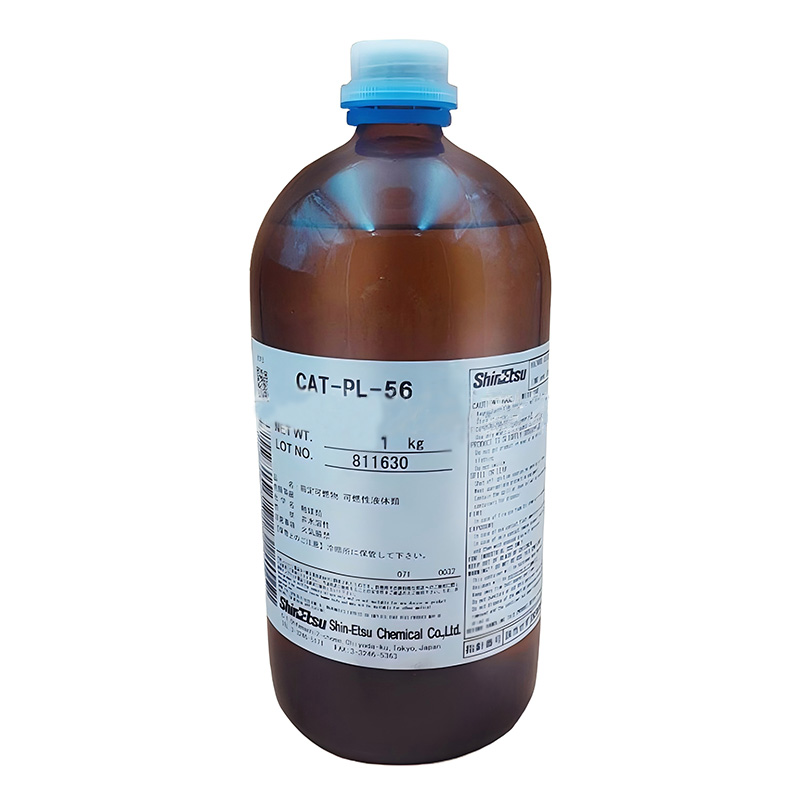

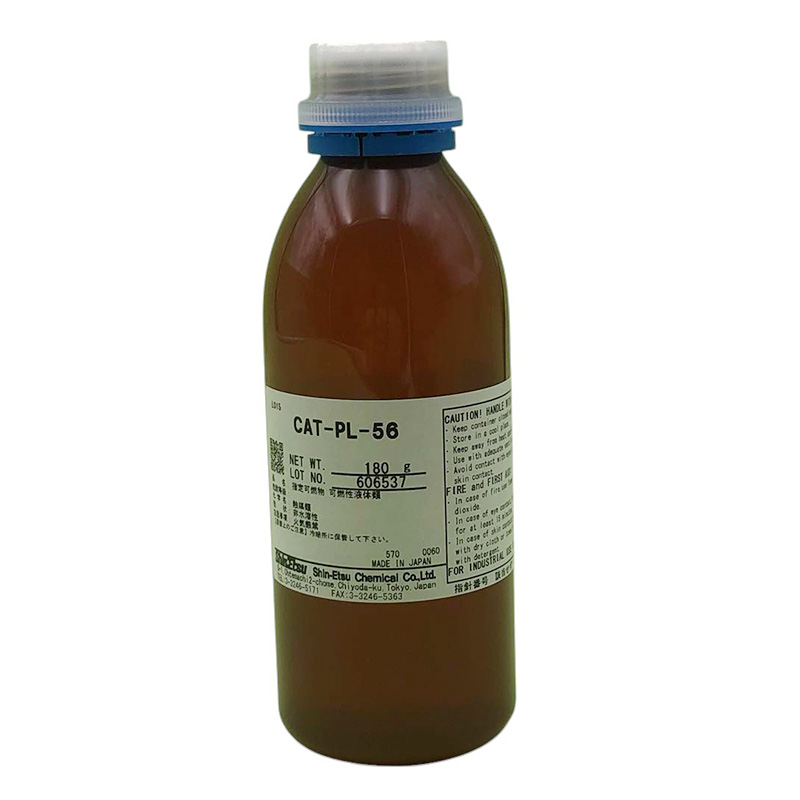

ShinEtsu CAT-PL-56 - Platinum Catalyst for Addition-Cure Silicone Rubber

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

Shin-Etsu CAT-PL-56 is a platinum catalyst primarily used to accelerate the curing reaction of addition-type silicone rubber. Its primary component is a polydimethylsiloxane solution, presenting as a colorless, transparent liquid with excellent fluidity and dispersibility. This product enables a stable and controllable cross-linking process in industrial silicone rubber applications, ensuring consistent and stable curing of the silicone rubber.

products parameters

| Composition: | Dimethylpolysiloxane |

| Appearance: | Clear Transparent Liquid |

| Flashing Point: | 315 Minimum |

| Freezing Point: | -50 Maximum |

| Refractive Index: | 1.403 |

| Packaging: | 180g, 1kg |

key features

Workability - CAT-PL-56 has a flash point of 315°C and remains stable even in high-temperature environments, preventing premature reactions that could affect handling. It remains liquid at -50°C, making it easy to store and transport at low temperatures.

Excellent Mold Release - Silicone rubber catalyzed by this catalyst exhibits a smooth surface after curing, offering excellent mold release properties. Mold-release agents (soapy water, wax, etc.) are unnecessary. Comparative experiments have shown that mold release forces for silicone rubber molds cured with CAT-PL-56 are over 30% lower than those without release agents, effectively reducing adhesion issues between the mold and the finished product.

Dimensional Stability - Silicone rubber cured with CAT-PL-56 exhibits minimal shrinkage during the crosslinking process, with test data showing post-cure shrinkage of less than 0.1%. This ensures that the finished product retains the mold's original dimensions and structure, ensuring the accuracy of complex or precision components.

Excellent Flowability - Due to its primary component of polydimethylsiloxane, CAT-PL-56 exhibits excellent flowability in its liquid state. Its refractive index of 1.403 indicates high purity and transparency, ensuring uniform distribution during mixing and pouring. In practical applications, even small details such as fingerprints and wood grain are fully restored after curing.

No Exothermic Reaction - CAT-PL-56 does not release additional heat during the curing process, making it a non-exothermic catalyst. Thermal monitoring experiments show that temperature fluctuations during the ambient curing stage are less than ±1°C, preventing material deformation or performance degradation due to exothermic reaction.

Electronics Industry - During the electronic component packaging process, CAT-PL-56 catalyzes the rapid curing of silicone rubber, forming a reliable protective layer. Tests have shown that silicone rubber cured with it exhibits excellent insulation properties, with a volume resistivity as high as 10¹⁴ Ω·cm, effectively preventing leakage and short circuits, and improving the durability of electronic devices.

Automotive Industry - The automotive industry places extremely high demands on the durability of seals and sensor protective layers. Silicone rubber cured with CAT-PL-56 maintains its elasticity within a temperature range of -40°C to 200°C, ensuring long-term stable operation of components in thermal cycling and vibration environments, significantly extending the service life of automotive parts.

Construction Industry - In the production of building seals and decorative materials, CAT-PL-56 is used to catalyze the curing of room temperature vulcanized silicone rubber. The cured material maintains weather resistance for over 20 years, with outstanding resistance to UV rays and humidity. It is suitable for glass curtain wall sealing and exterior wall waterproofing projects, enhancing the durability of buildings.

Industrial Manufacturing - In the manufacture of industrial molds and mechanical parts, CAT-PL-56's low-shrinkage cure ensures dimensional accuracy in finished products. Mold replication experiments have shown that molds cured with this catalyst can be reused over 500 times with a dimensional change rate of less than 0.1%, significantly improving production efficiency and cost-effectiveness.

Home Appliance Industry - In the manufacture of home appliances, CAT-PL-56 is used to mold silicone rubber seals and insulators. The cured silicone rubber exhibits excellent electrical insulation properties and high-temperature resistance, remaining stable in temperatures up to 180°C, ensuring the safety and reliability of home appliances over the long term.