What Are Release Agents?

Release Agents are specialty chemicals applied to mold surfaces to ensure that finished parts can be removed cleanly and efficiently. They act as an invisible barrier between the mold and the casting material, preventing adhesion, reducing surface defects, and extending the service life of the mold. Far beyond a simple lubricant, release agents are engineered to meet the demands of industrial Molding, high-precision manufacturing, and even sensitive cosmetic applications.

Table of Contents

Functional Role of Release Agents

The primary purpose of release agents is to control the interface between two surfaces during the molding process. By preventing materials from sticking, they achieve:

Smooth demolding without surface tearing

Consistent surface finish for parts or coatings

Extended mold durability by reducing wear

Increased efficiency in high-volume production lines

This makes them essential in industries ranging from plastics and elastomers to personal care formulations.

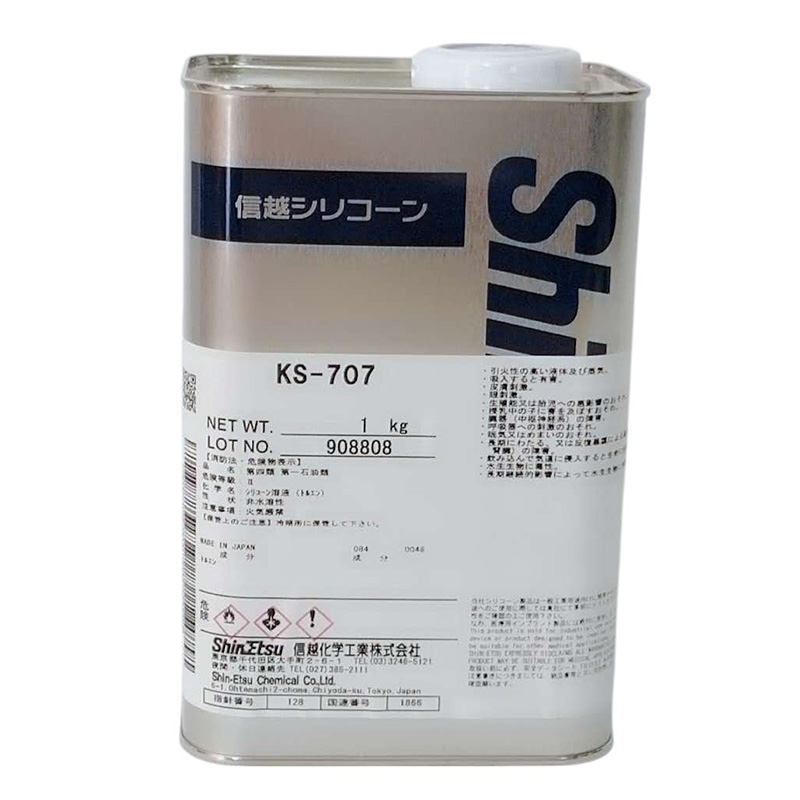

Shin-Etsu KS-707: Precision for Skincare Additives

KS-707 is designed with a unique balance of silicone chemistry, making it suitable for use in applications that involve skincare additives and delicate formulations. Its controlled release properties allow manufacturers to handle sensitive compounds without contamination or performance loss. By forming a uniform protective layer, KS-707 ensures compatibility and reliability where purity and safety standards are strict.

Shin-Etsu KM-742T: Industrial Performance

For heavy-duty industrial applications, KM-742T is a high-performance release agent engineered for molds exposed to intense processing cycles. It maintains stability under elevated temperatures, resists chemical degradation, and reduces production downtime. Industries such as automotive, construction, and Electronics benefit from KM-742T because it minimizes mold fouling and ensures consistent output across thousands of cycles.

Why Choosing the Right Release Agent Matters

Selecting a suitable release agent is not only about easier demolding. It also impacts the quality, cost, and sustainability of production:

Quality assurance: Avoiding sticking and surface defects ensures parts meet design standards.

Cost efficiency: Reducing scrap rates and extending mold life lowers operational costs.

Sustainability: High-quality release agents reduce waste, optimize energy use, and contribute to cleaner manufacturing processes.

Conclusion

Release agents are vital tools in modern manufacturing, bridging the gap between precision molds and finished products. Whether in the sensitive skincare sector with KS-707 or demanding industrial molding with KM-742T, choosing the right release solution ensures efficiency, durability, and superior product performance.

Our product range offers tailored release agents that meet both industrial-scale requirements and specialized additive formulations, providing reliability you can count on for long-term production success.