What is Silicone Rubber Made Of?

Silicone rubber is a synthetic elastomer created by combining siloxane polymers with various fillers, additives, and curing agents. Its backbone structure—composed of alternating silicon (Si) and oxygen (O) atoms—gives it unique flexibility, thermal resistance, and durability compared to traditional organic rubbers. Because of these properties, silicone rubber is widely used across industries such as Electronics, adhesives, coatings, and industrial lubrication.

Table of Contents

Basic Composition of Silicone Rubber

Polysiloxane Base (Silicone Polymer)

The core material that provides elasticity, weather resistance, and stability at high and low temperatures.

Different types of silicone polymers (e.g., dimethylsiloxane, methylphenylsiloxane, vinylsiloxane) are chosen depending on performance needs.

Fillers

Reinforcing fillers such as fumed silica improve mechanical strength and tear resistance.

Non-reinforcing fillers can be added to adjust viscosity, hardness, and processing characteristics.

Crosslinking Agents (Curing System)

Determines how the rubber cures into a solid elastomer.

RTV-1 Silicone Rubber: Cures with moisture in the air (one-component system).

RTV-2 Silicone Rubber: Requires mixing of two components (base and curing agent) for condensation cure or addition cure.

Additives

Pigments for coloration.

Flame retardants, heat stabilizers, or oil-resistant agents to meet special application requirements.

Types of Silicone Rubber

RTV-1 Silicone Rubber

Supplied as a single-component material. It cures upon exposure to atmospheric moisture. Commonly used in:Adhesives and sealants

Electronics encapsulation

Industrial coatings

Lubrication products

Primers for surface treatment

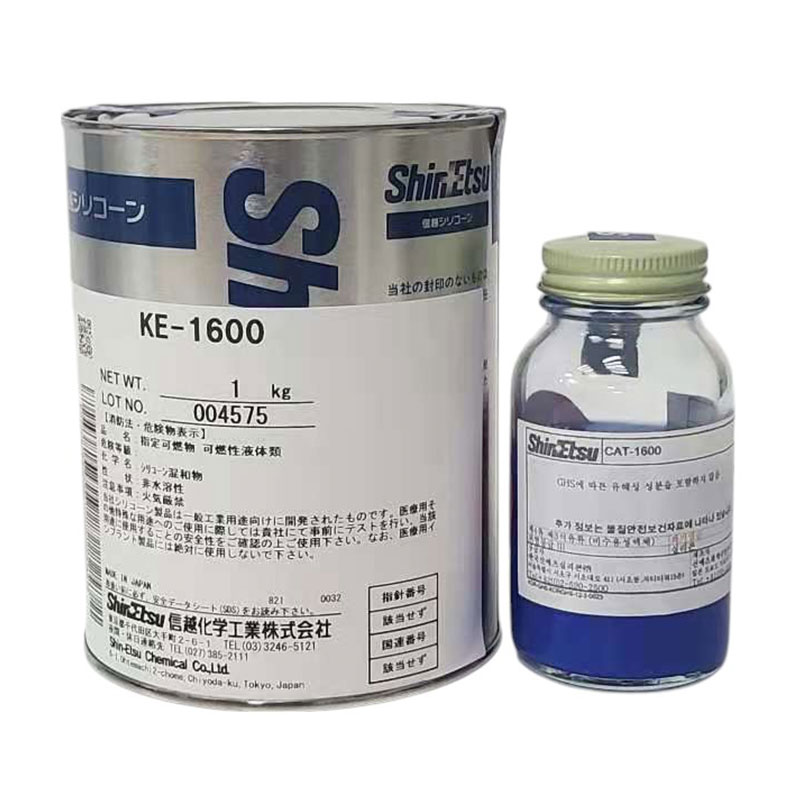

RTV-2 Silicone Rubber

A two-component system (base and catalyst) that cures either by condensation or addition reaction. It is highly versatile for:Mold making

Prototyping and Molding applications

Electronics potting and encapsulation

High-performance coatings

Specialized industrial components

Key Properties of Silicone Rubber

Wide Temperature Resistance: Performs from -60°C up to 250°C or higher.

Weather and UV Resistance: Maintains elasticity even with prolonged outdoor exposure.

Electrical Insulation: Excellent dielectric strength for electronic applications.

Chemical Resistance: Stable against oils, water, and many solvents.

Flexibility and Elasticity: Maintains softness and resilience across environments.

Conclusion

Silicone rubber is made from a siloxane polymer base reinforced with fillers, crosslinking agents, and additives. The combination produces an elastomer with outstanding thermal stability, electrical insulation, and mechanical durability. With both RTV-1 and RTV-2 product lines, silicone rubber can be adapted for adhesives, sealants, electronics, coatings, lubrications, and molding applications, making it an essential material for modern industry.