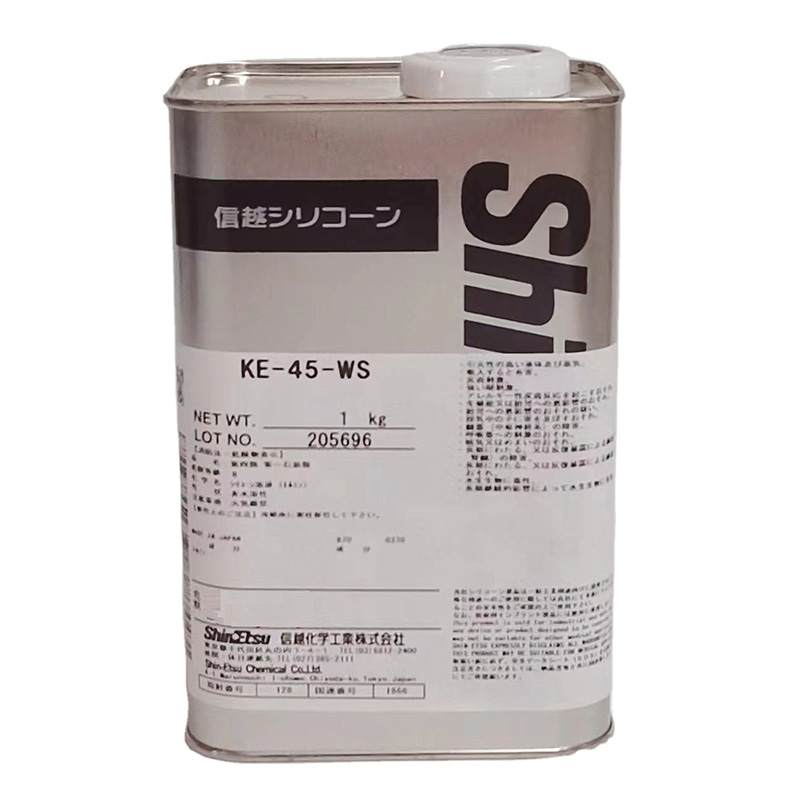

ShinEtsu KE-45 - Silicone Rubber for Electrical Bonding Adhesive Sealants

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-45 is a one-component, room-temperature curing silicone RTV sealant designed for general-purpose gasketing, sealing, and bonding. It adheres well to metals, plastics, glass, and ceramics without primers, forming a durable, flexible elastomer. KE-45T provides reliable performance over a wide temperature range, making it ideal for industrial, electronic, and precision applications requiring long-lasting seals.

products parameters

| Composition: | Dimethyl Silicone Oil |

| Appearance: | Transparent/ White/ Grey/ Red/ Black |

| Viscosity: | Paste |

| Specific Gravity: | Approximately 1.05 At 25°C |

| Temperature Resistance: | –60 °C To +180 °C |

| Packaging: | 100g, 330ml,1kg |

key features

Excellent Adhesion - KE-45 forms a strong bond to substrates such as metal, plastic, glass, ceramic, and rubber without the need for a primer. Shear strength tests show that its bond strength to aluminum exceeds 1.5 MPa, and to glass reaches 1.2 MPa, significantly exceeding that of standard general-purpose silicone rubber.

Curing System - KE-45 utilizes an oxime-based curing system that cures at room temperature upon reaction with moisture in the air. Its fast curing speed and controllable operation time make it suitable for assembly line production. Test data show that at 25°C and 50% RH, the surface-free time is 3 to 6 minutes, and the tack-free time is approximately 14 minutes.

Widely Compatible - KE-45 exhibits excellent adhesion to a wide range of surfaces, not only to plastics, metals, and painted surfaces, but also to glass and rubber substrates, maintaining long-term stability. Test results show that peel strength on various substrates is generally above 1.0 N/mm, with a retention rate exceeding 90% in thermal cycling tests.

Fast Curing - KE-45 has a tack-free time of just 3 to 6 minutes, and fully cures in significantly less time than standard silicone rubber at room temperature. This rapid cure reduces waiting time and improves assembly efficiency. Actual testing has shown that production lines using KE-45 have reduced overall processing time by over 15%, effectively improving process cycle time and throughput.

Heat Resistance - KE-45 operates within a temperature range of -60°C to +180°C, maintaining elasticity and stability in both extreme low and high temperatures. Experimental data shows no signs of brittle cracking after 100 hours at -60°C, and less than 10% strength loss after 500 hours at 180°C.

Electronics Industry - KE-45 is widely used for sealing and bonding electronic devices, such as protecting circuit boards, sensors, and connectors. Its insulation and moisture resistance ensure the stability of electronic components in high humidity and high voltage environments. Experiments have shown that electronic components encapsulated with KE-45 in high humidity environments maintain an insulation resistance of over 95%, significantly reducing failure rates.

Automotive Industry - In automotive manufacturing, KE-45 is commonly used for sealing lamps, body seams, and high-temperature components in the engine compartment. Road durability tests have shown that lamp seals using KE-45 remain intact after 1000 hours of salt spray testing, with no significant degradation in protective performance. This performance significantly improves the service life and reliability of automotive components.

Home Appliance Industry - KE-45 is primarily used for bonding and sealing in home appliances, such as in the assembly of components in washing machines, ovens, and refrigerators. Its temperature resistance range of -60°C to +180°C ensures stability in both high-temperature drying and low-temperature cooling environments. Experiments have shown that in a long-term operating environment with alternating hot and cold temperatures, the adhesion retention rate of KE-45 is as high as 92%, extending the overall life of home appliances.