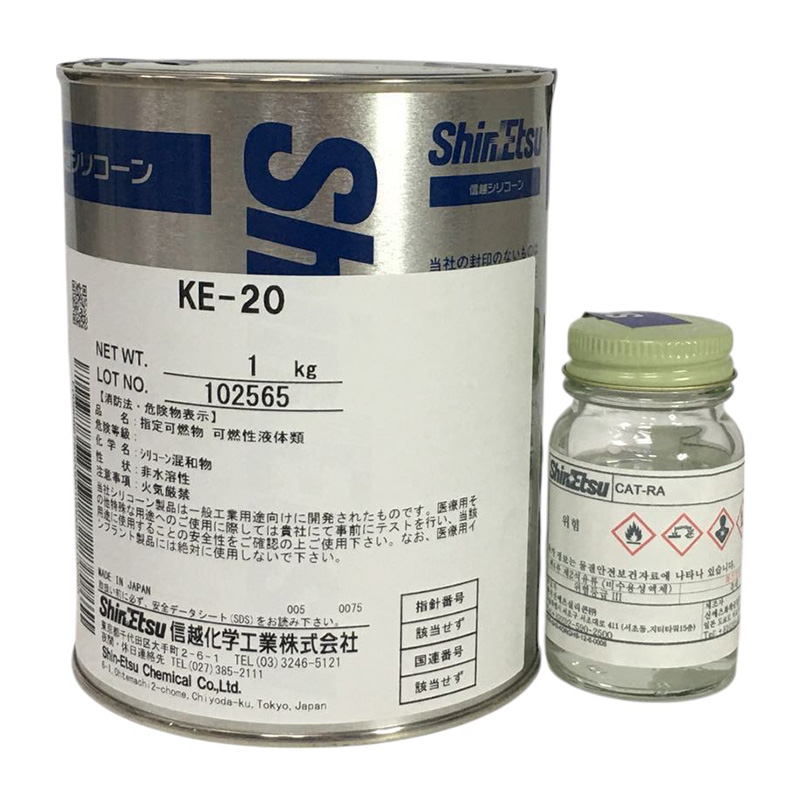

ShinEtsu KE-20 - Silicone Rubber Auxiliary Agent for Moldmaking

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-20 is a two-component, condensation-curing silicone rubber designed for moldmaking applications, particularly in synthetic leather production. It offers high elongation and tear strength, making it ideal for creating durable and flexible molds. It's excellent working properties ensure ease of use and consistent results in mold fabrication processes.

products parameters

| Composition: | Siloxanes And Silicones |

| Appearance: | Grayish White |

| Viscosity: | 77 Pa.s At 25 °C |

| Specific Gravity: | Approximately 1.18 At 25 °C |

| Flash Point: | 253 °C (open Cup) |

| Packaging: | 1kg |

key features

Ease of Processing - KE-20 mixes easily with the curing agent during operation, with a viscosity of 77 Pa·s at 25°C, ensuring uniform material flow during mixing and coating without noticeable bubbles or delamination. Adjusting the curing agent ratio allows for controllable working and curing times to meet diverse process requirements. Experimental results show that the working time tolerance is less than ±5 minutes, significantly improving mold manufacturing consistency.

Smooth Demolding - KE-20 requires no additional release agent for smooth demolding, ensuring a natural separation between the mold and the master mold. Test results show that under standard casting conditions, the demolding force required to separate the mold from the master mold is less than 0.2 N/cm², significantly lower than that of conventional silicone rubber.

Dimensional Stability - KE-20 exhibits extremely low volumetric shrinkage after curing, typically less than 0.2%, ensuring high-precision mold reproducibility after curing. Experimental results show that even after extended use, its dimensional deviation remains within ±0.1 mm, meeting the dimensional consistency requirements for precision molds.

Heat and Chemical Resistance - KE-20 has a flash point of 253°C, demonstrating excellent heat and chemical resistance. Testing has shown that it maintains over 90% of its mechanical properties after 100 hours of continuous operation at 200°C. Furthermore, after 72 hours of immersion in acidic or alkaline solutions, its physical strength decreases by no more than 8%. KE-20 also exhibits excellent chemical resistance, making it suitable for applications in harsh environments.

Non-Exothermic - KE-20 produces no significant heat during the curing process, with a temperature rise of less than 3°C. This property ensures that the curing process does not cause thermal damage to the master mold and prevents surface cracking caused by thermal stress. Field verification has shown that the master mold surface remains intact after 100 consecutive curing cycles, ensuring stable and repeatable mold manufacturing.

Consumer Goods Industry - KE-20 is widely used in consumer product mold manufacturing, such as artificial leather embossing molds and decorative parts molding molds. Its high tear strength and excellent flexibility ensure mold stability during long-term use. Experimental studies have shown that its mold life is over 30% longer than that of ordinary silicone rubber, significantly improving production efficiency and product quality.

Industrial Manufacturing - In general industrial production, KE-20 is used in mechanical component molds and prototypes. Its cure shrinkage is less than 0.2%, ensuring high-precision reproduction of part dimensions. Test data shows that after 500 continuous molding cycles, the mold dimensional accuracy deviation does not exceed ±0.1 mm, meeting the stringent requirements of industrial production for mold precision and stability.

Automotive Industry - KE-20 is suitable for mold manufacturing for automotive interior parts, seals, and functional components. Experimental studies have shown that after 500 cycles of high and low temperature cycling from -40°C to 120°C, the mold still maintains over 95% of its physical properties. This performance makes it an ideal material for molds in the automotive industry that require long-term durability and dimensional stability.

Furniture Industry - The KE-20 is widely used in the manufacture of furniture finish molds, such as those used to replicate surface textures like wood grain and leather. Its demolding force is less than 0.2 N/cm², ensuring efficient production even for large mold surfaces. Test results show that in the production of furniture decorative parts, the average mold life is increased by 25%, significantly reducing mold replacement frequency.