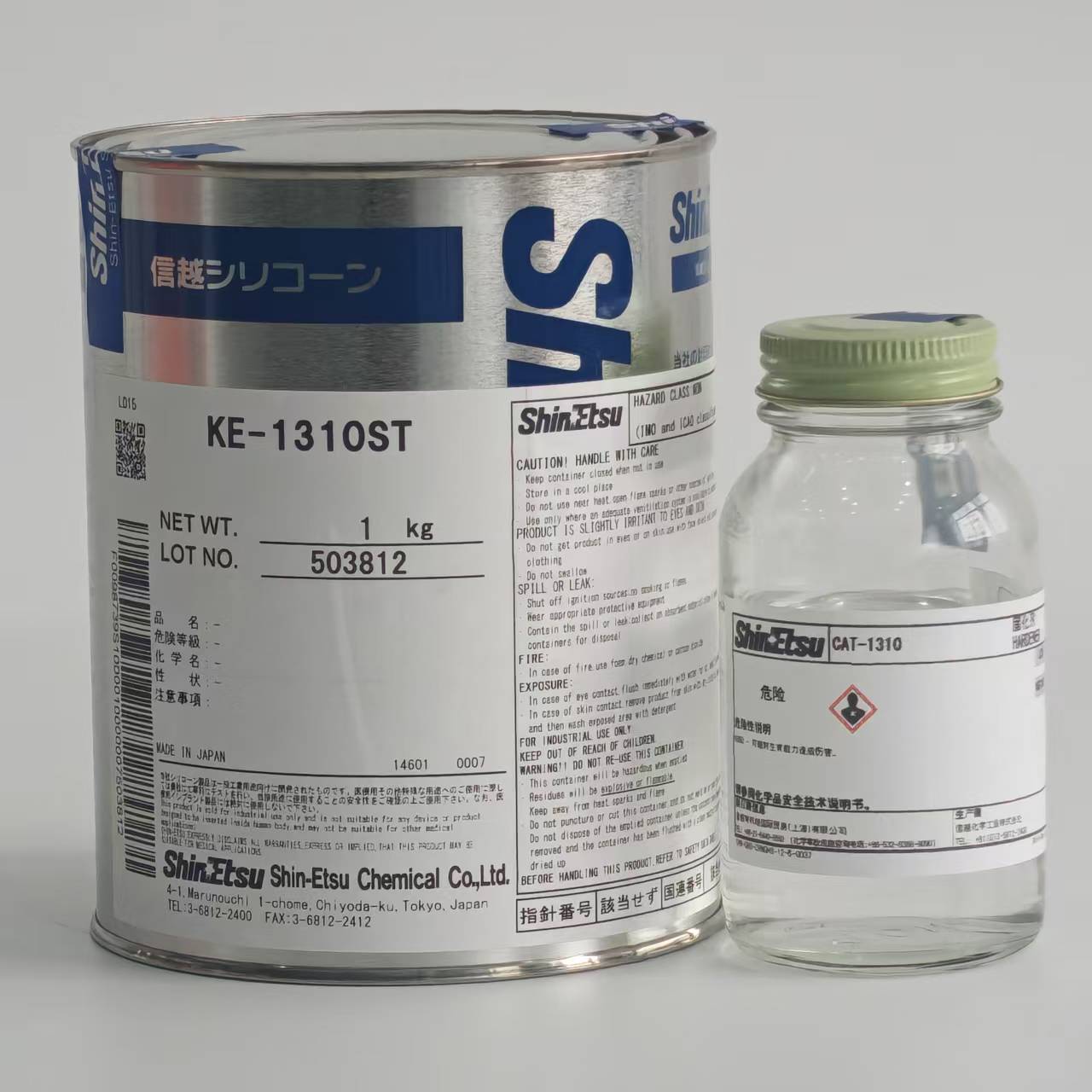

ShinEtsu KE-1310ST - Silicone Rubber for Embossing and Trademark Applications

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-1310ST is a transparent, high-strength silicone rubber material developed specifically for moldmaking. It's commonly used in applications such as embossing, logos, and decorative printing. This material combines excellent tear resistance, tensile strength, and flexibility while maintaining excellent clarity, making it ideal for precision molds requiring a balance between strength and clarity. Its 100:10 two-component ratio makes it easy to use and cures stably after mixing, producing highly elastic silicone products.

products parameters

| Appearance: | Transparent, Elastic Silicone Rubber |

| Mix Ratio By Weight: | 100:10 |

| Hardness: | ~40 Shore A (typical) |

| Density @ 23C (g/cm3): | 1.07 |

| Temperature Resistance: | -40°C To 175°C (typical Range) |

| Packaging: | 1.1kg Set, 20.1kg Set |

key features

High Platinum Content - KE-1310ST contains a high level of platinum catalyst, effectively preventing inhibition during the curing process. Its cure rate at 25°C is approximately 20% faster than that of standard silicone rubber, and its cure completion rate exceeds 98%. This ensures smooth curing even on complex substrates, making it suitable for demanding process environments.

High Tensile Strength - KE-1310ST's typical tensile strength is 7.5 MPa, exceeding the 4-5 MPa of standard room-temperature silicone rubber. In multiple tensile tests, the strength retention rate exceeded 85% after 1,000 cycles, making it less susceptible to breakage or permanent deformation during repeated use and extending the mold's service life.

Excellent Tear Resistance - The material boasts a tear strength of 28 kN/m, significantly exceeding the approximately 15 kN/m of standard silicone rubber. In mold applications with intricate details and sharp edges, it effectively resists damage caused by localized stress concentration, ensuring the integrity of the product after demolding.

Low Shrinkage - KE-1310ST has a linear shrinkage of less than 0.1%, maintaining high dimensional stability after curing. After 10 thermal cycle tests from -40°C to 175°C, sample dimensional change was kept within 0.05 mm, demonstrating its excellent suitability for high-precision mold manufacturing.

Optimal Mixing Ratio - The product utilizes a fixed 100:10 mixing ratio, enabling precise mixing and reducing the risk of defects caused by uneven curing. At this ratio, the cured product achieves a Shore A hardness of approximately 40, providing sufficient support while maintaining good flexibility and ensuring stable application.

Easy Mold Release - KE-1310ST exhibits a smooth surface after curing and excellent self-release properties. The peel force between the mold and the polyurethane or epoxy resin part is less than 0.4 N/mm, significantly reducing the need for external release agents, improving production efficiency, and ensuring detailed surface accuracy.

Mold Manufacturing - In the mold manufacturing industry, KE-1310ST is suitable for high-precision applications such as embossing molds and decorative printing molds. Its low shrinkage of less than 0.1% and tear strength of up to 28 kN/m ensure that molds maintain over 95% dimensional accuracy after 2,000 demolding cycles, significantly improving production efficiency and mold life.

Decorative Crafts - In the art and decorative industries, KE-1310ST is used to create transparent, high-detail decorative molds. Its light transmittance of up to 90% ensures the integrity and visual impact of details in decorative printing and logo creation. Its tear resistance ensures stability during complex molding processes.

Precision Casting - In the casting of jewelry and small precision products, KE-1310ST, with a Shore A hardness of approximately 40, combines flexibility with sufficient support. Tests show that after 50 casting cycles, the mold surface wear rate is less than 2%, far superior to traditional mold materials, ensuring consistent and precise product quality.

Textile Labels - In textile processing, the KE-1310ST is commonly used for silicone label and printed label molds. Its temperature resistance range is -40°C to 175°C, allowing it to withstand high-temperature curing and subsequent ironing processes. In high-temperature embossing tests, the mold performed 10,000 cycles without deformation, ensuring high efficiency and consistency in label production.