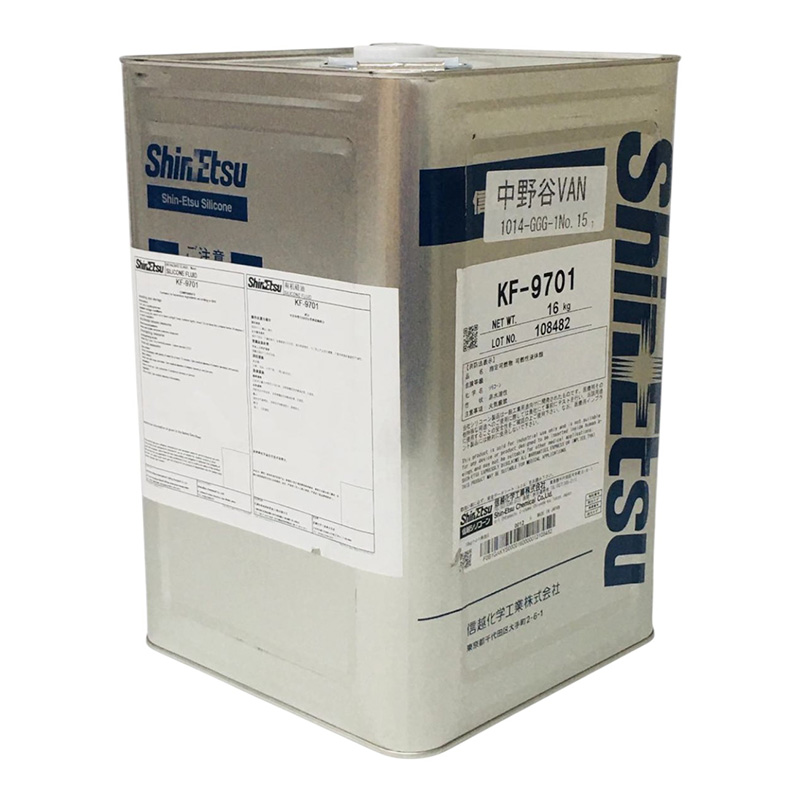

ShinEtsu KF-9701 – Low Viscosity Reactive Silanol Terminated Polydimethylsiloxane for Industry Uses

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KF-9701 is a reactive silanol-terminated silicone fluid designed to improve the handling quality and surface feel of coated materials. Users experience smoother processing during application because the fluid spreads uniformly and integrates easily into different formulation systems. Its clear and low-viscosity profile contributes to stable blending without visible residue, offering a clean and consistent working experience in textile finishing, release coatings, and protective surface treatments. The product is widely valued in manufacturing environments where efficient wetting and controlled deposition are required to maintain uniformity from the first stage of coating to final curing.

products parameters

| Composition: | PDMS |

| Appearance: | Clear, Colorless Liquid |

| Viscosity 25 °C Mm²/s: | 60 Mm²/s |

| Specific Gravity At 25 °C: | 0.977 |

| Refractive Index At 25 °C: | 1.404 |

| Packaging: | 16kg |

key features

Heat Stability – KF-9701 maintains stable performance during high-temperature drying and curing steps due to its silanol-terminated PDMS structure, supported by a viscosity of approximately 60 mm² per second at 25 degrees Celsius. This stability minimizes degradation during processing and ensures predictable film formation. It also maintains molecular integrity when exposed to prolonged thermal exposure, helping users achieve consistent quality across multiple production batches.

Low Volatility – KF-9701 demonstrates reduced migration and low volatilization levels due to its controlled molecular weight distribution and reactive silanol groups. This property minimizes loss during high-temperature operation and reinforces fixation on substrate surfaces. With a specific gravity of 0.977 at 25 degrees Celsius, it maintains uniform deposition, supporting reliable performance in long-run manufacturing.

Surface Control – KF-9701 improves slip, gloss balance, and anti-blocking performance by forming stable surface layers supported by a refractive index of 1.404 at 25 degrees Celsius. These measured characteristics help regulate film appearance and optimize handling during the coating or finishing process. Users benefit from predictable surface behavior that contributes to high-quality finished products.

Better Dispersibility – KF-9701 offers enhanced dispersibility in both water-based and solvent-based systems due to its chemical reactivity and controlled molecular weight. Its clear liquid form supports uniform emulsification during agitation, minimizing separation and enabling stable mixing without additional mechanical force. This performance improves formulation flexibility and reduces the risk of uneven distribution.

System Compatibility – KF-9701 is compatible with multiple formulation types, including waterborne, solvent-based, and one-hundred-percent solid systems. Its reactive silanol termination assists bonding with diverse organic and inorganic components. The product’s consistent viscosity and clean appearance enable smooth integration during batching, supporting efficient production workflows.

Textile Finishing – KF-9701 is widely used in textile finishing where controlled hydrophobicity and surface smoothness are required to improve durability and tactile feel. Its reactive silanol groups form stable bonds with fabric substrates, ensuring long-lasting water repellency and efficient processing during high-speed finishing lines. These performance attributes also support consistent results during repeated washing and drying cycles.

Release Coatings – KF-9701 is applied in release coating formulations to help generate uniform parting layers on paper, film, or metal surfaces. Its low viscosity and controlled reactivity ensure that the product spreads evenly, enabling clean release behavior in molding and adhesive applications. This consistent performance reduces defects and stabilizes production output.

Construction Materials – KF-9701 is used in construction materials where surface protection and moisture resistance are primary requirements. Its hydrophobic properties and strong surface bonding ability enhance the durability of treated substrates. These functions also support long-term performance under varying environmental conditions encountered in construction applications.

Electronics Manufacturing – KF-9701 is suitable for electronic component processing where low surface energy and controlled deposition help improve part cleanliness and moisture resistance. Its consistent fluidity and reactive bonding behavior allow precise coating on delicate surfaces. This improves operational stability during device assembly and handling.