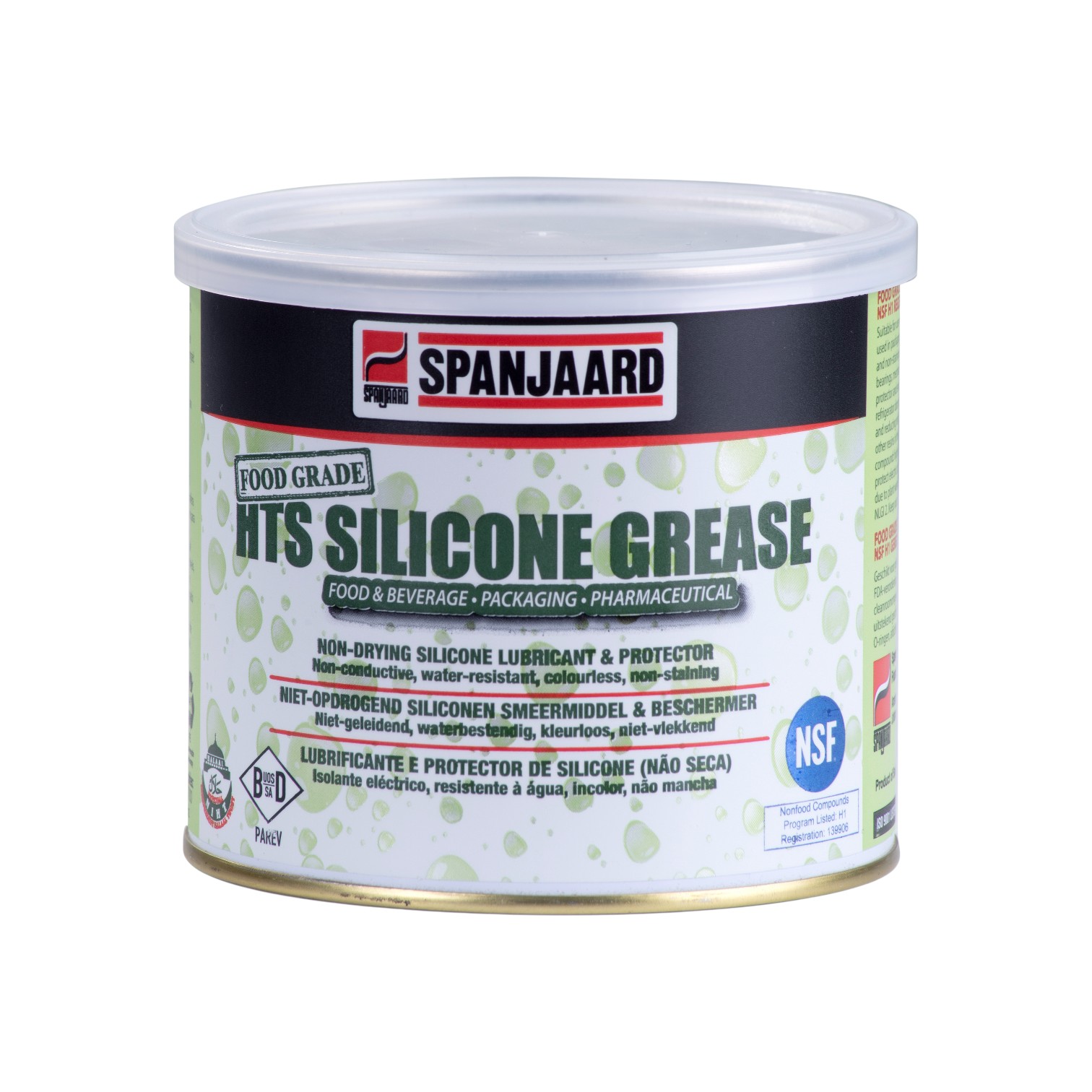

Spanjaard HTS Silicone Grease – Food Grade Non-Drying Silicone Lubricant & Protector

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

Spanjaard HTS Silicone Grease is a food-grade, non-drying silicone lubricant formulated for long-term use on rubber, plastic, and metal interfaces where moisture resistance, electrical insulation, and material compatibility are critical. In use, it provides a smooth, stable lubricating feel that does not harden, migrate, or wash away easily, maintaining consistent performance over extended service intervals. Its paste consistency allows controlled application, ensuring reliable coverage on seals, O-rings, and moving components without dripping or spreading beyond the intended contact area.

Products parameters

| Consistency – NLGI Grade: | 2 |

| Worked Penetration At 25°C: | 1/10mm 275 |

| Colour: | White Translucent |

| Thickener: | Silica |

| Package: | 500g |

Key features

Water Resistance - The silicone grease exhibits strong water repellency and maintains lubrication performance in wet or humid environments. Standard water washout testing indicates minimal loss of lubricating film under continuous moisture exposure, supporting stable operation in washdown or condensation-prone systems. This resistance helps prevent corrosion on adjacent metal surfaces while preserving lubrication integrity on rubber and plastic parts.

Electrical Insulation - Spanjaard HTS Silicone Grease is electrically non-conductive, with high dielectric strength suitable for insulating applications. The silicone base provides volume resistivity typically exceeding 10¹⁴ Ω·cm, reducing the risk of leakage currents or short circuits. This property allows safe use on electrical connectors, terminals, and sealing interfaces where electrical isolation is required.

Consistency Stability - The grease is manufactured to an NLGI Grade 2 consistency, providing a balance between spreadability and mechanical stability. Worked penetration values remain within controlled ranges after mechanical shear testing, indicating resistance to softening or oil separation. This ensures predictable application thickness and long-term retention on contact surfaces.

Material Compatibility - The chemically inert silicone formulation shows low reactivity with common elastomers and plastics. Compatibility testing demonstrates no swelling, cracking, or embrittlement when used on materials such as EPDM, nitrile rubber, silicone rubber, and most engineering plastics. This stability supports extended service life of seals, gaskets, and molded components.

Rubber Seals - The Spanjaard HTS Silicone Grease is used to lubricate rubber seals where smooth motion and surface protection are required. Controlled film thickness reduces friction during repeated compression cycles while preventing seal sticking or tearing. This contributes to consistent sealing performance over long operating periods.

O-Rings - Applied to O-rings to support assembly and operational movement under pressure. The NLGI Grade 2 structure allows even distribution without excessive squeeze-out. This helps reduce wear and extrusion risks during dynamic or static sealing conditions.

Plastic Gears - Used on plastic gear systems to lower friction and noise while maintaining material integrity. The silicone base does not attack common thermoplastics and remains stable under moderate mechanical loads. This supports predictable gear engagement and reduced surface wear.

Valves - Suitable for valve lubrication where smooth actuation and moisture resistance are required. The grease maintains consistency across a wide temperature range, helping ensure stable valve movement without sticking or drying. This supports reliable control in repeated open-close cycles.

Gaskets - Applied to gaskets to enhance sealing performance and ease installation. The non-drying nature prevents hardening at the interface, allowing the gasket to adapt to surface irregularities over time. This helps maintain long-term sealing effectiveness.

Locks - Used in lock mechanisms to provide lubrication without attracting dirt or causing material degradation. The grease forms a stable lubricating layer that reduces internal friction and supports consistent mechanical response. This contributes to smoother operation and reduced wear.

Slides - Applied to sliding components where controlled movement and moisture protection are required. The paste consistency allows precise placement along guide surfaces. This ensures steady sliding behavior without lubricant migration.

Mechanisms - Suitable for general mechanical assemblies involving mixed materials. The grease supports predictable friction control and surface protection under repeated motion. This helps extend maintenance intervals and improve operational reliability.