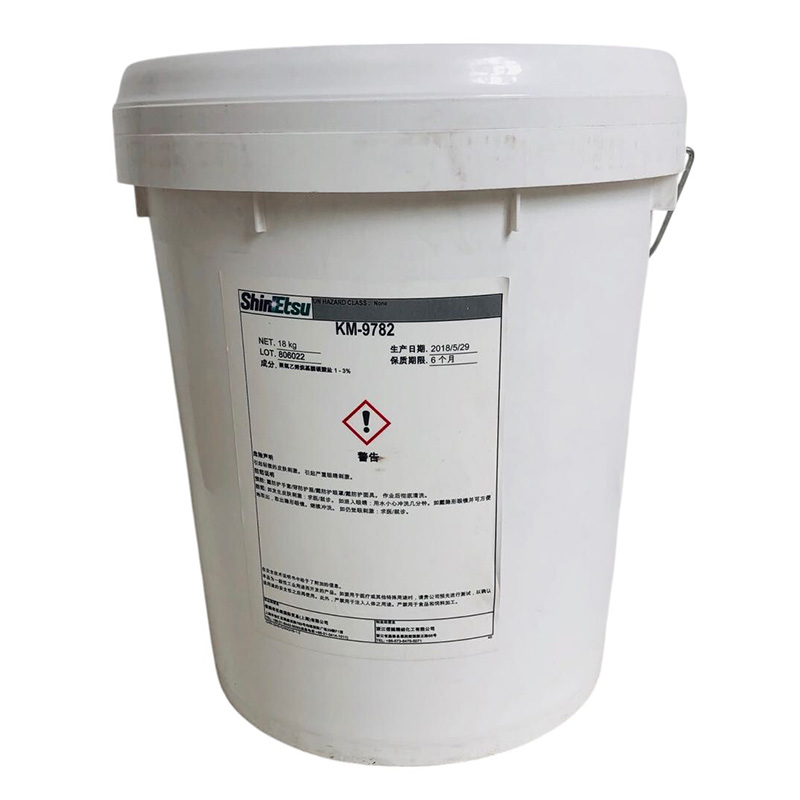

ShinEtsu KM-9782 - Food Grade Release Agent for PET film with High Temperature Resistence

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KM-9782 is a water-dispersible silicone emulsion release agent free from alkylbenzene-based emulsifiers, meeting the safety standards of the Japan Hygienic Olefin and Styrene Plastics Association for food container packaging. Its low viscosity and weak anionic properties ensure easy dilution and spraying, making it ideal for food-grade applications.

products parameters

| Composition: | Silicone Emulsion |

| Appearance: | Milky White Liquid |

| Nonvolatile Content: | 37% (105°Cx3h) |

| Ionic Type: | Nonionic |

| Packaging: | 16kg, 18kg |

key features

Wide Application Range - KM-9782 is primarily composed of a silicone emulsion with a non-volatile content of 37%, exhibiting excellent coating and film-forming properties. Its near-neutral pH allows for application on rubber, plastic, metal, and food-grade molds without affecting material properties.

Excellent Mold Release - This product exhibits low surface energy and is non-reactive with most organic materials, effectively reducing interfacial adhesion between the mold and the part. Experimental data shows that KM-9782 results in a mold surface residue rate of less than 0.3%, significantly superior to conventional oil-based release agents. This ensures a smooth finish and reduces subsequent cleaning steps.

High Temperature Resistance - KM-9782 is stable in both hot and cold environments, maintaining excellent mold release performance within a temperature range of -20°C to 200°C. Even in high-temperature hot pressing processes, the product release pass rate remains above 95%, demonstrating its reliable performance across a wide temperature range and its suitability for industrial processing under diverse thermal conditions.

Excellent Resilience - Due to its ability to form a flexible, elastic coating on the fiber surface, the fabric exhibits excellent resilience. In standard fabric testing, after 500 bends, the stretch recovery exceeded 90%, effectively enhancing the material's durability and shape retention during repeated use.

Strong Chemical Stability - KM-9782 is chemically inert at room temperature and remains stable in dilute acids and alkalis, preventing corrosion, swelling, or deformation of molds or finished products. Chemical resistance testing shows that its performance retention exceeds 92% when used within a pH range of 3 to 10, ensuring stable operation even in challenging working conditions.

Rubber Industry - During rubber product molding, KM-9782 significantly reduces adhesion between the part and the mold, ensuring smooth demolding. Application tests have shown that demolding efficiency increased by 20% in tire and seal production, while also reducing mold cleaning frequency and extending mold life, making it suitable for large-scale rubber product production.

Resin Industry - Resin products are prone to mold sticking during molding. The low surface tension of KM-9782 effectively addresses this pain point. In practical applications, the surface finish of resin parts has been improved to below Ra 0.9, and the qualified product yield has increased to over 97%, significantly reducing scrap and enhancing processing efficiency.

Die-casting Industry - In metal die-casting molds, KM-9782 forms a stable barrier at high temperatures, preventing direct contact between the metal and the mold. After high-temperature die-casting tests at 200°C, the mold surface remained clean and residue-free, and demolding time was shortened by 15%, reducing production cycle time and improving metal processing efficiency.

Surface Treatment - KM-9782 can serve as a coating barrier during surface treatment processes, improving surface lubricity and contamination resistance. When used as a pre-treatment for metal coatings, it can reduce surface roughness by 30%, effectively improving the uniformity and adhesion of subsequent coatings and ensuring the quality of the final product.

Synthetic Fibers - During synthetic fiber processing, KM-9782 forms a flexible film on the fiber surface, enhancing its anti-stick properties and flex resistance. Textile testing has shown that treated fibers increase their elongation at break by 15%, effectively enhancing fiber durability and fabric lifespan, meeting the demands of high-strength textile applications.