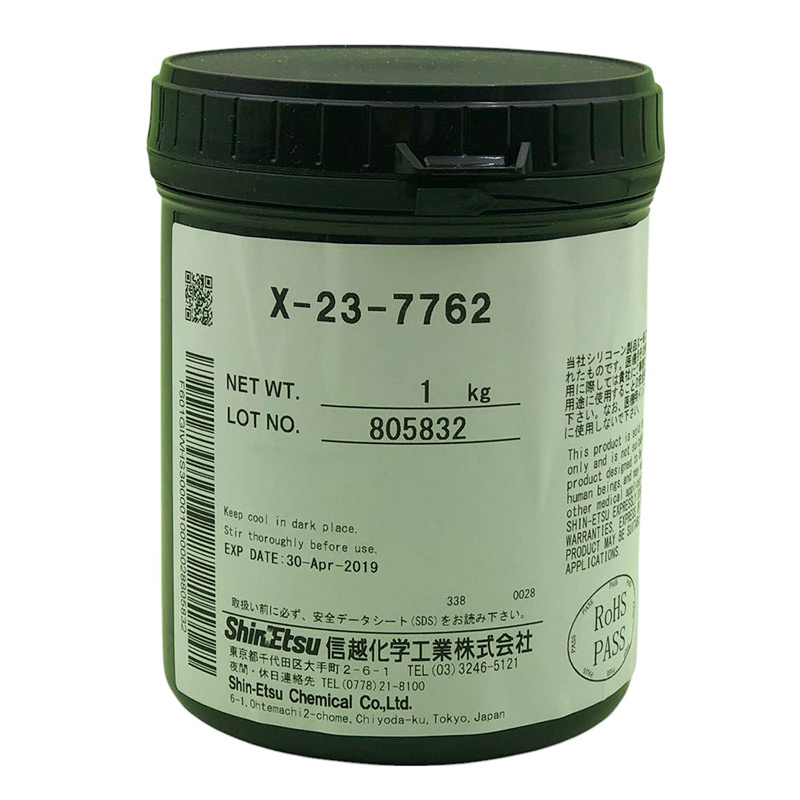

ShinEtsu X-23-7762 - Thermal Conductive Grease for Electronics

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

X-23-7762 is a silicone-based thermal grease formulated for excellent heat transfer between electronic components and heat sinks. It resists pump-out, oxidation, and evaporation under thermal stress, ensuring long-term reliability. Suitable for CPUs, GPUs, power modules, and industrial semiconductors requiring efficient cooling.

PRODUCTS PARAMETERS

| Composition: | Dimethyl Silicone Oil |

| Viscosity: | 180 (Pascal Second) |

| Specific Gravity: | Approximately 2.6 At 25 °C |

| Appearance: | Grey Paste |

| Thermal Conductivity: | ~6.0 W/m·K |

| Packaging: | 3g Pieces, 1kg |

key features

High Thermal Conductivity - X-23-7762 boasts a thermal conductivity of approximately 6.0 W/m·K, significantly higher than the 1.5 to 3.0 W/m·K of common silicone greases. This effectively reduces the thermal resistance between electronic components and heat sinks. In actual thermal testing of CPUs and GPUs, this material reduced core temperatures by over 10°C, ensuring stable operation of high-performance devices.

Suitable Viscosity Range - The product's viscosity of 180 Pa·s ensures excellent application during dispensing, screen printing, or doctor blade coating. Its fluidity ensures uniform distribution while avoiding material waste or buildup due to excessive flow, ensuring a stable thermal interface.

Uniform and Stable Mixing - X-23-7762 utilizes a homogeneous and stable paste formula, preventing delamination or settling during long-term storage and repeated heating. After 1000 hours of high-temperature aging testing, its thermal conductivity retention rate exceeded 95%, demonstrating its ability to maintain consistent thermal performance over long-term use.

Environmental Compliance - This product complies with RoHS and REACH regulations. Test data shows that it contains no hazardous substances such as lead, cadmium, and mercury, and has extremely low levels of volatile organic compounds. This not only ensures product compliance in the consumer electronics and automotive industries, but also aligns with the global trend towards the use of green and environmentally friendly materials.

Semiconductor Electronics - In high-performance semiconductor devices such as IGBTs and MOSFETs, heat dissipation is crucial for lifespan and efficiency. X-23-7762's high thermal conductivity ensures temperature control during full-load chip operation, reducing the risk of breakdown due to overheating. Data shows that under continuous high-load testing, chip lifespan using this material is extended by over 20%.

LED Lighting Industry - LED light sources require extremely high heat dissipation performance, otherwise they will accelerate light degradation. X-23-7762 creates a uniform thermal interface between the LED package and the heat sink substrate, reducing the operating temperature of the LED chip by 8°C to 12°C in real-world measurements, thereby extending light source life and maintaining stable brightness.

Automotive Electronics - Automotive ECUs, battery management systems, and power modules often operate in high-temperature environments. X-23-7762 maintains stable thermal conductivity across a temperature range of -45°C to 200°C, effectively surviving extreme operating conditions such as those in the engine compartment and improving the reliability of automotive electronic components.

Power Modules - High current operation in power modules for industrial equipment and energy systems generates significant heat. Applying X-23-7762 reduces internal module temperature rise by over 15%, helping to improve operational continuity and safety while reducing downtime and maintenance associated with poor heat dissipation.