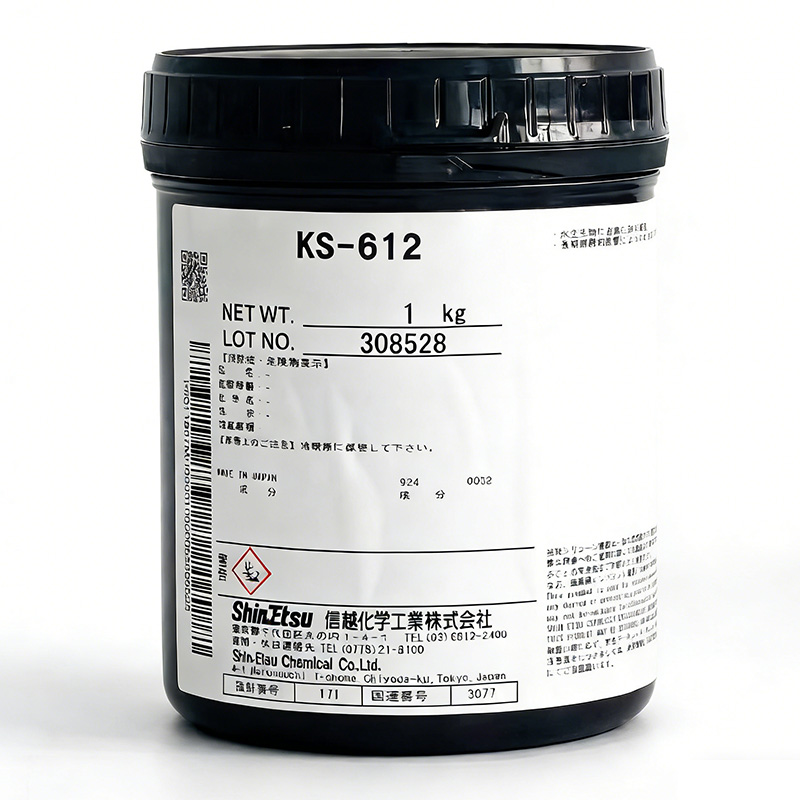

ShinEtsu KS-612 – High-Temp Silicone Fluid for Specialty Lubricity Applications

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

ShinEtsu KS-612 is a high-temperature silicone fluid. KS-612 delivers stable handling behavior, smooth application, and predictable flow during high-temperature operation. Its clear appearance and consistent fluid response support clean processing, reduced residue concerns, and reliable long-term use in demanding thermal environments without frequent maintenance or replacement interruptions.

Products parameters

| Composition: | High-Temperature Silicone Fluid |

| Appearance: | Clear Liquid |

| Viscosity 25 °C mm²/s: | ~800 |

| Specific Gravity At 25 °C: | ~1.00 |

| Refractive Index At 25 °C: | ~1.403 |

| Packaging: | 1KG |

Key features

High-Temp Stability - KS-612 is formulated with a silicone backbone designed for thermal endurance. With a kinematic viscosity of approximately 800 mm²/s at 25 °C, the fluid maintains lubrication integrity during continuous exposure to temperatures exceeding 200 °C. This stability minimizes viscosity collapse and supports long service life in heat-intensive environments.

Viscosity Control - The controlled viscosity of approximately 800 mm²/s at 25 °C enables stable film formation under load. This viscosity level balances flow and retention, reducing excessive migration while maintaining adequate surface coverage. Consistent viscosity across operating temperatures supports predictable system performance.

Density Balance - KS-612 has a specific gravity of approximately 1.00 at 25 °C, allowing neutral density behavior in mechanical systems. This property supports uniform distribution without sedimentation or flotation. Stable density improves formulation consistency and reduces recalibration during extended operation.

Optical Clarity - With a refractive index of approximately 1.403 at 25 °C, KS-612 exhibits clear liquid appearance suitable for visual inspection. Optical clarity supports contamination monitoring and process quality control. The stable refractive value reflects consistent molecular structure under thermal stress.

Oxidation Resistance - KS-612 resists oxidative degradation during prolonged heat exposure due to its silicone molecular structure. The formulation maintains chemical integrity under continuous air contact at elevated temperatures. This resistance reduces residue formation and supports extended lubrication intervals.

Specialty Lubrication - KS-612 is used in specialty lubrication systems requiring stable performance under high thermal load. Its viscosity and oxidation resistance support reduced friction in continuously heated mechanical interfaces. This improves reliability where conventional lubricants degrade rapidly.

High-Temp Bearings - In bearing assemblies operating above standard temperature ranges, KS-612 provides consistent lubrication without carbon buildup. The stable viscosity supports smooth rotational motion and controlled wear rates. This application extends bearing service life in heated equipment.

Industrial Processing - KS-612 is applied as a process fluid in industrial systems exposed to repeated thermal cycles. Its controlled flow behavior supports uniform lubrication and release performance. This reduces downtime associated with fluid breakdown or instability.

Heat-Exposed Components - For moving components subjected to radiant or conductive heat, KS-612 maintains a stable lubricating layer. The silicone fluid resists hardening and viscosity loss during temperature fluctuation. This supports consistent mechanical motion and reduced maintenance frequency.

Specialty Mechanical Systems - KS-612 is suitable for mechanical systems requiring precise lubrication under thermal stress. Its density and viscosity characteristics support accurate dosing and controlled distribution. This improves operational stability in specialized high-temperature assemblies.