ShinEtsu G-40 Series - High Temperature Lubrication Of Sealed Bearings

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

Shinetsu G-40 Series Silicone Lubricants are based on silicone oil, mixed with appropriate proportions of tackifiers and antioxidants. Unlike ordinary petroleum oils, they can be used over a wide temperature range, have excellent thermal and oxidative stability, are water-resistant, and do not undergo chemical changes, making them suitable for general machinery.

products parameters

| Composition: | Silicone Oil |

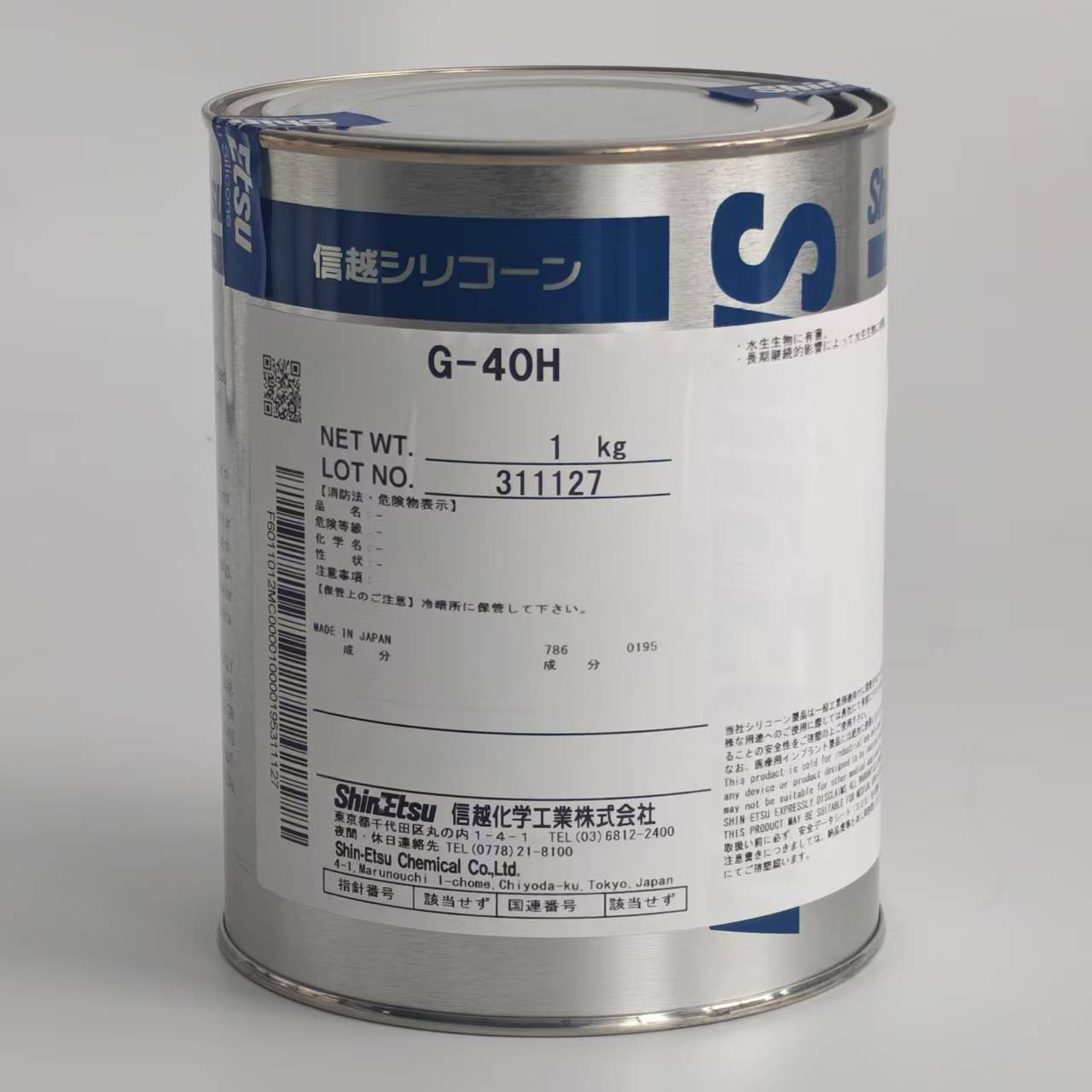

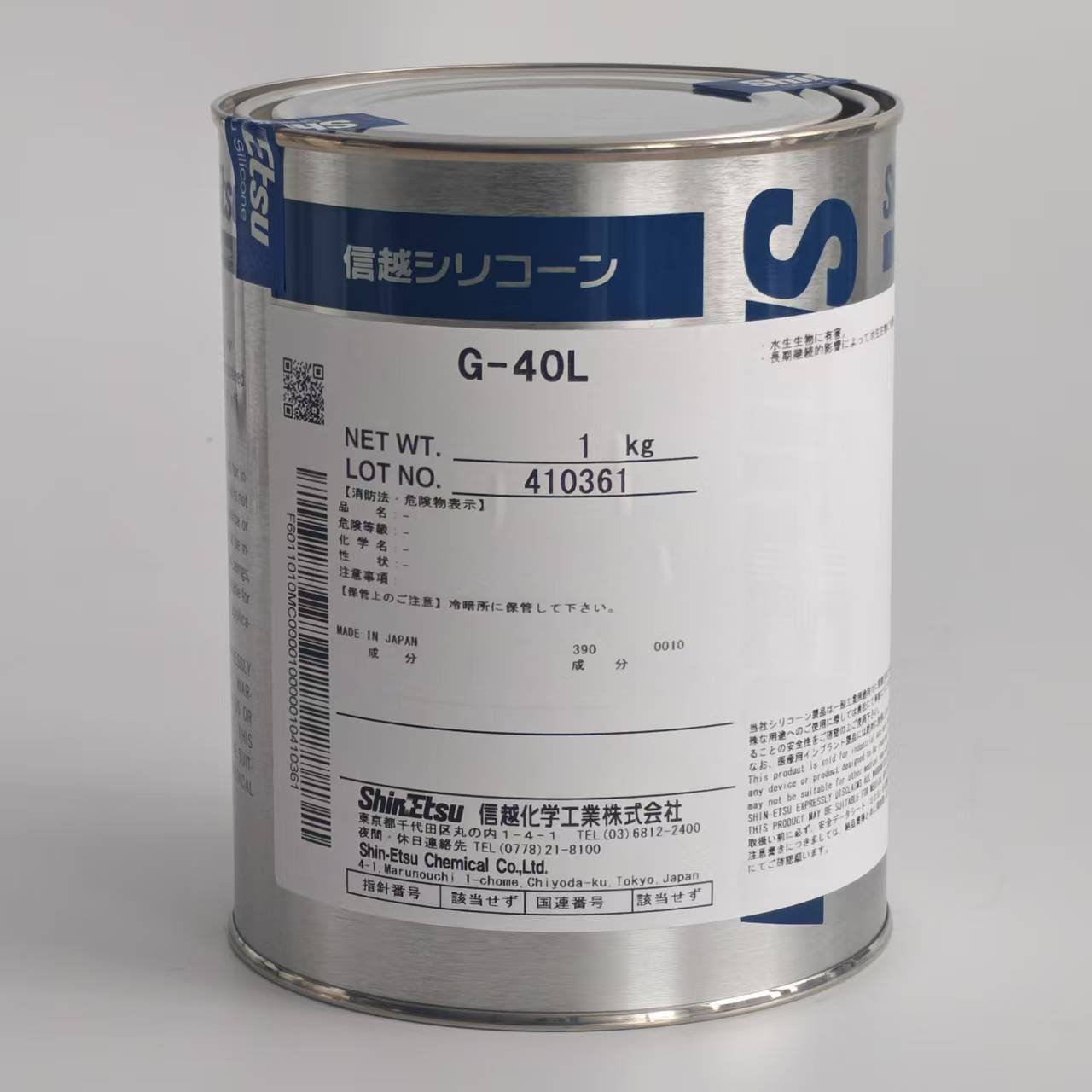

| Appearance: | Beige Grease(L,M); Brown Grease(H) |

| Specific Gravity: | 1.05- 1.06 |

| Drop Point: | +200°C |

| Temperature Resistance: | -30°C To 200°C |

| Packaging: | 100g,1kg(G-40M); 1kg(G-40H);1kg(G-40L) |

key features

Temperature Resistance - Shinetsu G-40 Series Silicone Lubricants have an operating temperature range of -30°C to 200°C. They remain flexible and fluid at low temperatures and maintain a stable structure at high temperatures, without significant decomposition or loss.

Insulation - Due to its silicone oil base, the G-40 Series exhibits excellent electrical insulation properties. Its specific gravity is 1.05-1.06 g/cm³, maintaining a uniform structure and resisting the presence of conductive impurities. In electrical insulation strength tests, the grease can withstand an electric field of 10 kV/mm without breakdown, effectively preventing leakage and short circuit risks.

Moisture Resistance - G-40 Series greases exhibit excellent water repellency and humidity resistance. Even in environments with a relative humidity above 95%, the lubricating layer applied to metal surfaces remains intact, without emulsification or softening due to water absorption.

Corrosion Protection - Metal specimens coated with G-40 Series exhibited excellent corrosion resistance in a 120-hour salt spray test, with no visible rust or corrosion spots. The silicone oil and antioxidants in its formula form a stable protective film on the metal surface, blocking oxygen and corrosive media, effectively extending the service life of metal components and reducing maintenance costs.

Efficient Lubrication - G-40 Series grease provides significant lubrication even with minimal application. Tribological tests have shown that a coating of just 0.05 g/cm² on the lubricated surface reduces the coefficient of friction by over 30% and reduces wear by 25%.

Industrial Equipment - In equipment such as machine tools, bearings, gears, and valves, G-40 Series lubrication maintains stable lubrication in environments with high loads and frequent temperature fluctuations. Continuous operation tests have shown that using G-40 Series lubricants in highly loaded bearings extends operating life by over 40%, reducing equipment downtime due to wear and improving production line reliability.

Electronics Industry - In electronic connectors, switches, and insulating components, G-40 Series lubricants' dielectric strength and moisture resistance provide reliable protection. Its 10 kV/mm dielectric strength ensures stable operation in humid and high-voltage environments, reducing the risk of short circuits or failures and extending the lifespan of electronic products.

Automotive Industry - In automotive engine compartments, sensors, and electrical connectors, G-40 Series lubricants maintain stable performance in operating environments ranging from -40°C to 120°C. Road durability tests have shown that automotive parts coated with this grease maintain excellent lubrication even after 100,000 kilometers of operation, effectively reducing maintenance requirements and improving vehicle reliability.