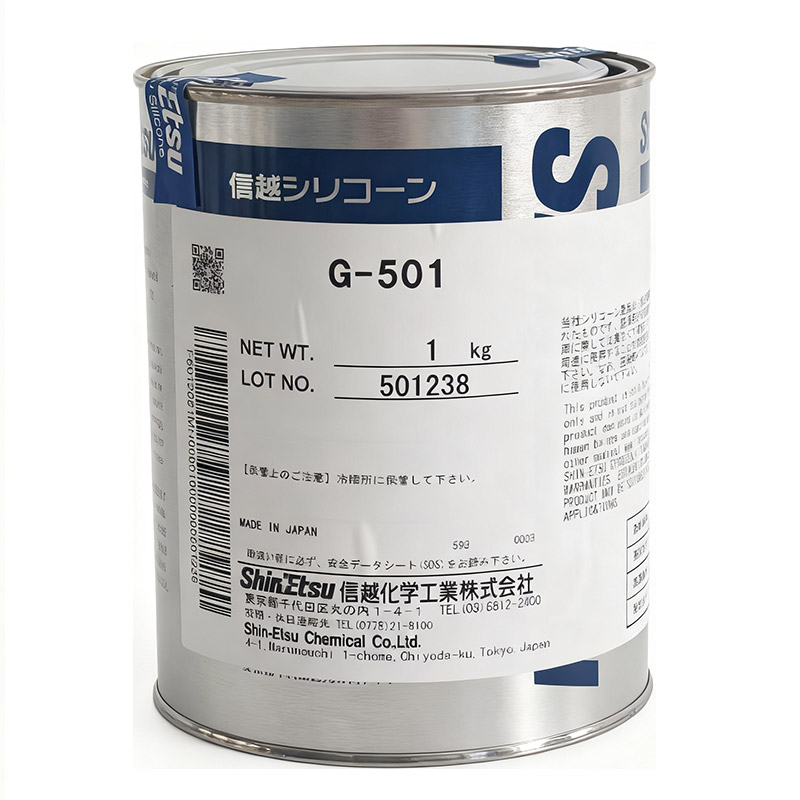

ShinEtsu G-501 Lubrication Grease for Bearing Parts

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

G-501 is a high-performance silicone grease formulated for use in precision mechanical and electrical applications. It provides superior lubrication and protection against wear, oxidation, and corrosion across a wide temperature range. With excellent thermal stability and moisture resistance, G-501 is ideal for sealing and lubricating electronic components, connectors, and precision instruments. Its stable consistency ensures reliable long-term performance in demanding environments.

products parameters

| Composition: | Dimethyl Silicone Oil |

| Appearance: | White To Pale Yellow Grease |

| Viscosity: | Medium Consistency |

| Specific Gravity: | Approximately 1.05 At 25°C |

| Temperature Resistance: | –50 °C To +200 °C |

| Packaging: | 80g, 1kg And 16kg |

key features

Temperature Resistance - G-501 operates in a temperature range of -50°C to 200°C, maintaining its softness and lubricity even at extremely low temperatures and resisting decomposition or evaporation at high temperatures. Experimental data shows that after 500 hours of continuous operation at 180°C, lubricity retention exceeds 85%, demonstrating excellent temperature resistance.

Insulation - G-501, based on dimethyl silicone oil, exhibits excellent electrical insulation properties. With a specific gravity of approximately 1.05 g/cm³, it maintains stable dielectric strength, effectively preventing risks associated with leakage or short circuits.

Moisture Resistance - G-501 maintains excellent stability even in high-humidity environments. Its silicone oil base offers excellent water repellency, preventing the lubricating layer from emulsifying or failing even at 95% relative humidity.

Corrosion Resistance - G-501 effectively prevents corrosion when applied to metal surfaces. Salt spray test results show that no noticeable rust spots were observed on the sample after 120 hours of salt spray exposure. The antioxidant ingredients in its formula form a stable barrier on metal surfaces, isolating air from corrosive media, thereby extending the service life of metal components and reducing equipment maintenance costs.

Highly Effective Lubrication - G-501 delivers significant lubrication even at low usage levels. Friction and wear tests show that even at a dosage of just 0.05 g/cm², the coefficient of friction is reduced by over 30% and the wear volume is reduced by over 25%.

Industrial Equipment - In industrial equipment such as machine tools, bearings, gears, and valves, G-501 maintains stable lubrication under long-term operating conditions. Industrial test data shows that lubrication performance remains above 85% even after 500 hours of continuous operation in highly loaded bearings, effectively preventing downtime and failures caused by wear and extending equipment life.

Electronics Industry - In electronic connectors, switches, and circuit boards, G-501 boasts a dielectric strength of up to 10 kV/mm, providing reliable electrical protection for components. Experimental studies have shown that electronic contacts lubricated with G-501 have a 40% reduction in failure rate, significantly improving the stability and reliability of electronic products.

Automotive Industry - In automotive engine components, sensors, and electrical connectors, G-501 grease maintains stable performance in environments ranging from -40°C to 120°C. Road durability tests have shown that sensors lubricated with G-501 maintain excellent performance after 100,000 kilometers, significantly reducing the frequency of repairs and replacements.

Aerospace - G-501's temperature resistance of -50°C to 200°C ensures stability in extreme high and low temperature environments for electronic modules, connectors, and seals in aerospace applications. Experiments have shown that, under conditions simulating the low pressure and temperature differentials experienced at high altitude, the operating life of components lubricated with G-501 is increased by 35%, effectively enhancing equipment reliability.

Gaming Equipment - In high-precision game controllers, joysticks, and esports equipment, G-501's medium viscosity provides smooth operation and maintains stability during extended use. Tribological testing shows that G-501 reduces friction on operating components by 28%, significantly improving user comfort and device responsiveness.