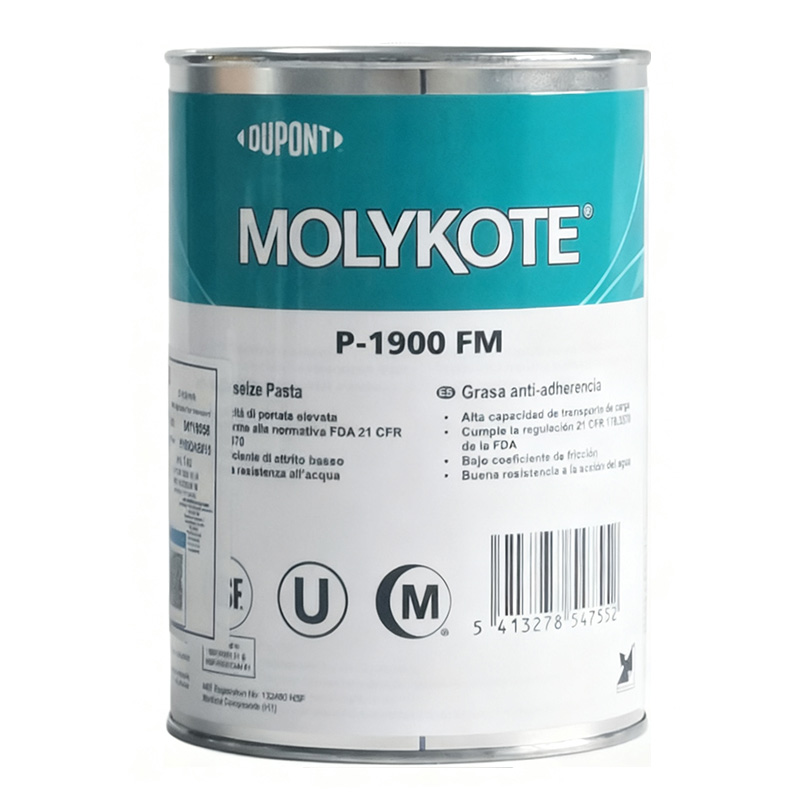

MOLYKOTE® P-1900 FM - Food-Grade Lubricant Grease for Processing Equipment And Sliding Surface Protection

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

MOLYKOTE® P-1900 FM is a high-performance, food-grade anti-seize and lubricating grease designed to protect metal surfaces exposed to heavy mechanical loads and sliding motion. It is formulated with a mineral oil base and a synergistic blend of solid lubricants to deliver long-lasting protection against friction, wear, and corrosion. The product meets FDA regulation 21 CFR 178.3570 and NSF H1 classification standards, ensuring its suitability for incidental food contact in food and beverage processing environments.

products parameters

| Composition: | Silicone Grease |

| Appearance: | White |

| Penetration (unworked): | 290-340 Mm/10 |

| Density: | 1.11 G/cm3 |

| Viscosity At 25°C (77°F): | 34mm2/s |

| Service Temperature Range: | -30 °C To +300 °C |

| Packaging: | 1kg |

key features

Low Friction Coefficient - MOLYKOTE® P-1900 FM demonstrates a significantly reduced coefficient of friction compared to conventional mineral greases. In laboratory tribology tests, the average coefficient of friction remains below 0.08 under a 1,000 N load. This low-friction property minimizes start-up torque and wear in metal interfaces, improving operational efficiency and reducing mechanical stress.

Food-Safe Certification - The product fully complies with FDA regulation 21 CFR 178.3570 and holds NSF H1 classification for incidental food contact. It is formulated without toxic heavy metals or reactive additives, ensuring compatibility with food production and packaging systems. Rigorous material compatibility testing confirms no migration or contamination risk under standard processing temperatures.

PFAS-Free Composition - MOLYKOTE® P-1900 FM contains no intentionally added PTFE or per- and polyfluoroalkyl substances. This environmentally responsible design ensures full compliance with current global sustainability standards. In chemical stability tests conducted at 250°C for 100 hours, no breakdown or release of fluorinated residues was detected, confirming both material integrity and workplace safety.

Food & Beverage Processing - MOLYKOTE® P-1900 FM is widely used in processing and packaging machinery, including mixers, conveyors, filling lines, and ovens. It provides consistent lubrication for bearings, sliding guides, and joints exposed to frequent washing and high heat. Endurance testing showed up to 30% lower wear on stainless-steel components and zero contamination in finished products, ensuring compliance with hygiene standards.

Automotive Industry - The grease is suitable for assembly points requiring non-toxic and thermally stable lubrication. It ensures clean, low-friction performance for threaded joints and sliding metal parts in vehicle assembly lines. Comparative torque testing confirmed a 25% reduction in required fastening force, ensuring precise component installation and reduced tool wear during mass production.

Plastics Processing - MOLYKOTE® P-1900 FM serves as an anti-seize agent in injection molding and extrusion machinery. It resists adhesion of plastic residues to metal molds and reduces wear on clamping units. Under continuous operation at 250°C, it maintained film integrity for over 500 cycles, ensuring consistent mold release and preventing product surface defects.

Industrial Machinery - The product delivers reliable lubrication for high-speed bearings, linear guides, and mechanical couplings operating in variable load conditions. Tribological testing under 1,200 N contact pressure showed a 40% reduction in friction coefficient and 50% decrease in surface pitting compared with standard industrial greases, extending maintenance intervals.

Packaging Equipment - MOLYKOTE® P-1900 FM is ideal for sliding and rotating parts in sealing machines, labeling units, and conveyors used in packaging systems. It maintains stable viscosity between -30°C and +300°C, preventing film breakdown during rapid thermal cycling. In long-term operation, film retention efficiency exceeded 95% after 1,000 hours, ensuring uninterrupted line performance and equipment longevity.