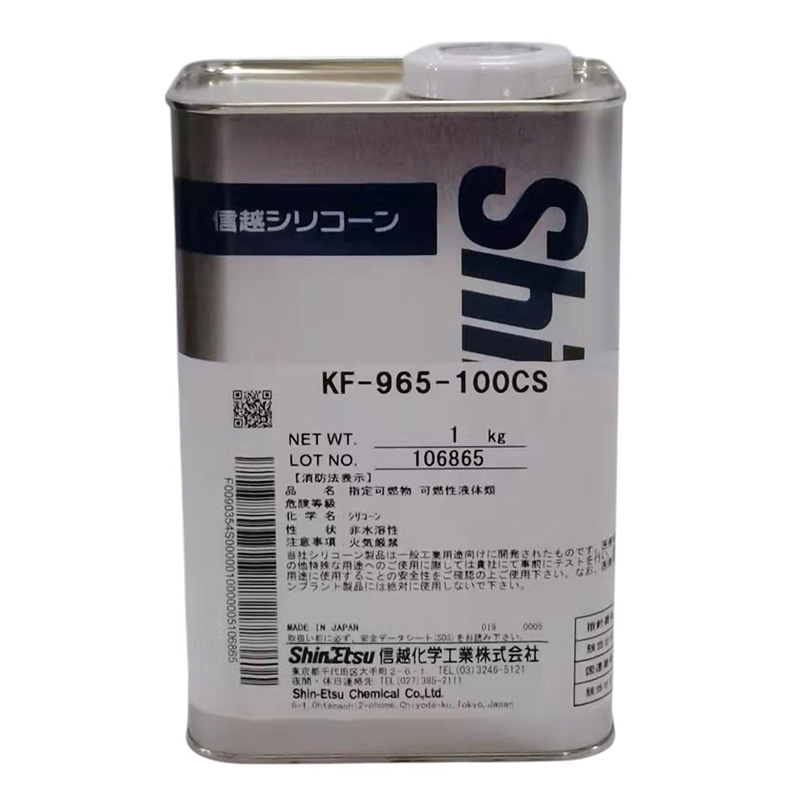

ShinEtsu KF-965-100cs - Phenyl Silicone Oil for High Temperature Resistence

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KF-965-100cs is a high-temperature lubricant and thermal conductor formulated with dimethyl silicone fluid. This material offers excellent thermal stability, oxidation resistance, and a wide operating temperature range, maintaining stable performance under both high and low temperature conditions. Its dark brown appearance provides consistent flow during use, providing reliable protection for equipment. It is ideal for high-performance lubricants, electrical insulation, and release agents.

products parameters

| Composition: | Dimethyl Silicone Fluid |

| Appearance: | Dark Brown Liqui |

| Viscosity: | 100 Mm²/s (25°C) |

| Specific Gravity (25°C): | 0.965 |

| Pour Point: | -50°C Maximum |

| Flashing Point: | 315°C Minimum |

| Packaging: | 1kg, 16kg |

key features

High Temperature Resistance - KF-965-100cs has excellent heat resistance, with a flash point exceeding 315°C, making it resistant to decomposition in prolonged high-temperature environments. Testing shows that after 500 hours of continuous operation at 250°C, the viscosity change is less than 10%, maintaining stable lubrication and heat transfer properties.

Low Temperature Resistance - The product maintains excellent fluidity even in low-temperature environments, with a pour point below -50°C. Its viscosity remains stable at -40°C, with no noticeable solidification or performance degradation. This performance ensures operability in low-temperature conditions, making it suitable for applications in cold regions or for low-temperature storage.

Oxidation Resistance - KF-965-100cs exhibits excellent thermal-oxidative stability. After 1000 hours of operation in an oxidizing environment at 200°C, the oxidation product content remains below 0.5%. This antioxidant property prevents rapid degradation of the lubricant at high temperatures, extending its service life and reducing replacement frequency and maintenance costs.

Low Surface Tension - This product's low surface tension effectively wets surfaces such as metal, glass, and resin, improving penetration and uniformity. Test data shows that its surface tension is less than 20 mN/m, approximately 30% lower than that of conventional mineral oils, significantly enhancing coating, spreading, and coverage performance.

Stable Viscosity - KF-965-100cs demonstrates outstanding viscosity consistency, with a dynamic viscosity of 100 mm²/s at 25°C and a specific gravity of 0.965. Over the temperature range of -40°C to 200°C, viscosity fluctuation is less than ±12%.

Rubber Industry - In the rubber industry, KF-965-100cs is used as a mold release agent and processing aid. Its low surface tension allows it to form a uniform film on the mold surface, effectively reducing resistance during demolding of rubber products. Application tests have shown that the use of this material improves demolding efficiency by 25% and reduces mold residue by 40%, significantly improving production efficiency.

Die-Casting Industry - In the die-casting field, KF-965-100cs is used as a highly effective mold release agent and lubricant. Its high-temperature resistance ensures stability in the molten metal state, forming a protective layer on the mold surface to prevent sticking. Industrial application data shows that the use of this material can extend mold life by 20% and reduce downtime caused by sticking.

Synthetic Fibers and Textiles - In synthetic fiber and textile processing, KF-965-100cs is used as a spinning oil and softener. Its excellent low surface tension properties improve fiber surface lubricity and reduce static electricity accumulation. In tests at spinning speeds up to 5000 m/min, the yarn breakage rate was reduced by 15%, and the surface smoothness of the finished fiber was significantly improved.

Electronics and Precision Machinery - KF-965-100cs is commonly used as an insulating oil and lubricant in electronics and precision machinery. Its stable dielectric properties effectively prevent leakage and short circuits, while also reducing friction and wear in bearings and sliding parts. Long-term operating tests have shown that the use of this product increases the life of precision components by 30% and significantly reduces the failure rate.

Resins and Plastics - In resin and plastic processing, KF-965-100cs can be used as an additive to improve material flow and mold release properties. In practical applications, the addition of 0.5%-1% of KF-965-100cs to thermoplastic molding reduces surface defects by 20% and significantly improves molding consistency.

Surface Treatment - In the surface processing industry, KF-965-100cs is used for protective and wettability treatments on metal, ceramic, and glass surfaces. Its low surface tension and stability ensure more uniform coatings and improved adhesion. Tests show that the contact angle of treated metal surfaces decreases by 15°, enhancing surface wetting.

Automotive and Aerospace - In the automotive and aerospace industries, KF-965-100cs is used as a high-temperature lubricant and heat dissipation medium. Its thermal stability makes it widely used in engines and high-temperature mechanical parts. Engine durability testing shows that after using this fluid, engines remain stable after 1000 hours of continuous operation at 200°C, with a 35% reduction in wear rate and a longer service life.