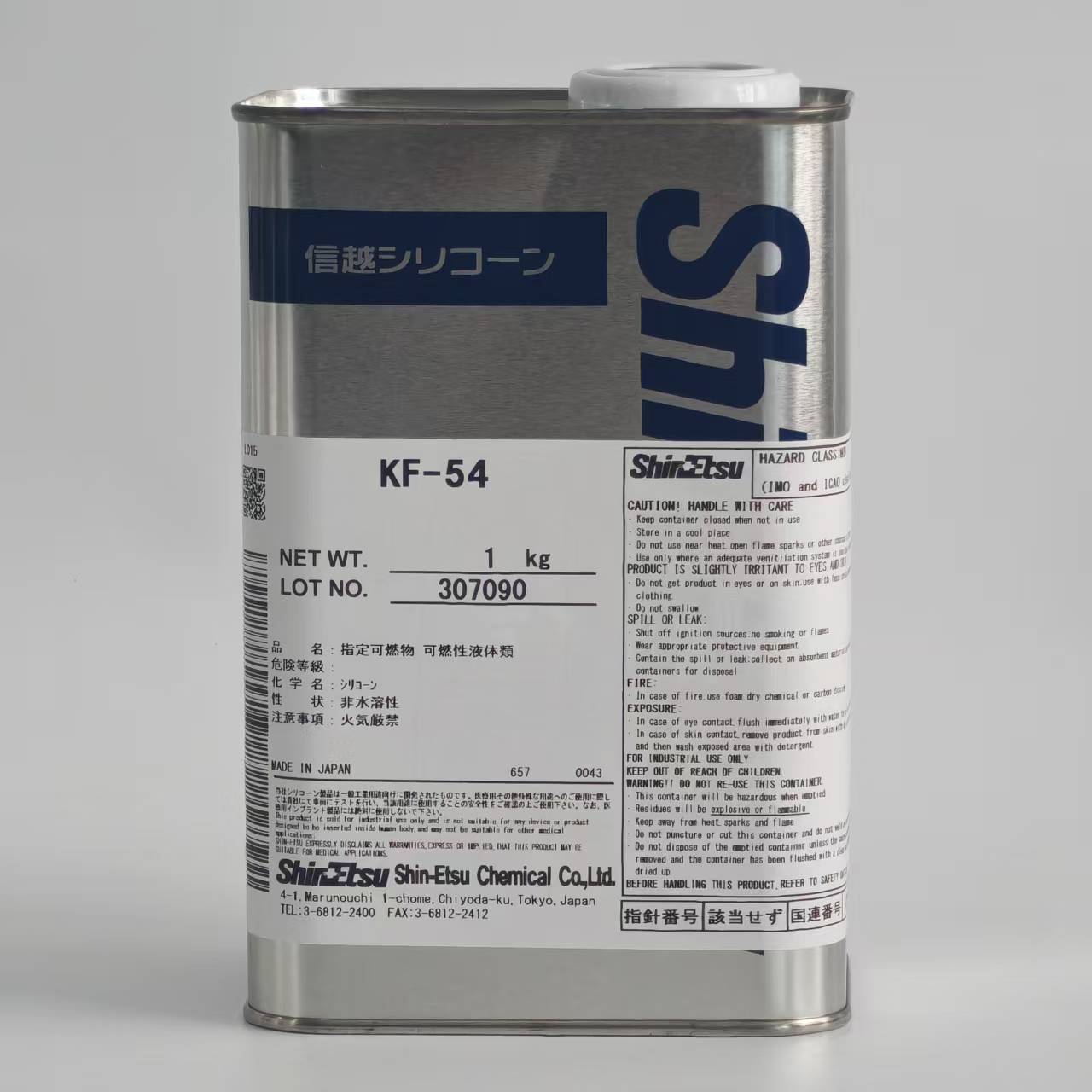

ShinEtsu KF-54 - Phenylmethyl Silicone High-Temperature Lubricant Fluid

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KF-54 is designed for use as a high-temperature lubricant and heat transfer medium. With excellent thermal stability, oxidation resistance, and wide operating temperature range with superior resistance to heat and oxidation, it is ideal for high-performance lubricants, electrical insulation, and release agents.

products parameters

| Composition: | Diphenyl Dimethicone |

| Viscosity: | 400 Mm²/s (25°C) |

| Appearance: | Colorless Fluid |

| Specific Gravity: | 1.07 |

| Flashing Point: | >315°C |

| Packaging: | 1kg, 18kg |

key features

High Temperature Resistance - KF-54 boasts exceptional thermal stability, maintaining long-term performance in environments exceeding 300°C. Its flash point exceeds 315°C, and it exhibits no decomposition or significant performance degradation after repeated heating cycles. Thermal aging tests show that after 500 hours at 250°C, the viscosity change is less than 5%.

Stable Viscosity - KF-54 exhibits minimal viscosity change across various temperatures. At 25°C, the viscosity is approximately 400 mm²/s, and even at temperatures up to 200°C, the viscosity fluctuation remains within a ±10% range. This ensures consistent lubrication and heat transfer even with frequent temperature fluctuations, preventing system efficiency degradation caused by sudden changes in viscosity.

Wetting Properties - KF-54 has a low surface tension, demonstrating excellent wetting and release properties. Its surface tension is approximately 15% lower than that of traditional silicone oils, enabling rapid spreading on surfaces such as metal, plastic, and rubber, improving coverage uniformity.

Chemically Inert - KF-54 is completely non-corrosive to metals, plastics, and elastomers, remaining chemically inert. With a specific gravity of 1.07, the liquid is stable in acidic and alkaline environments and does not react with common industrial materials.

Low Volatility - KF-54 has a volatile content of less than 0.5%, resulting in extremely low evaporation losses in long-term high-temperature environments. In a 72-hour continuous heating test at 200°C, the mass loss rate was less than 0.3%. This low volatility ensures long-term lubrication during equipment operation, reducing maintenance frequency and replacement costs due to lubricant loss.

Cosmetics - KF-54 can be used as a heat-resistant lubricant and protective ingredient in high-end cosmetics and personal care products. Its chemical inertness ensures it is non-irritating to the skin, while its low volatility ensures improved stability during long-term use. Adding KF-54 to products like lipstick and liquid foundation improves product smoothness and film-forming properties, meeting consumer demand for comfort and long-lasting wear.

Industrial Machinery - KF-54 is widely used for lubrication and heat transfer in high-temperature machinery. With a flash point exceeding 315°C, it can withstand the extreme conditions of mechanical friction and heat buildup. In practical applications, lubrication tests on large compressors and vacuum pumps have shown that the equipment maintained high performance after 3,000 hours of operation, significantly reducing wear problems caused by insufficient lubrication.

Coatings and Inks - KF-54 performs wetting and dispersing functions in coatings, inks, and polishes. Its low surface tension ensures uniform distribution between the pigment and the substrate, improving coating adhesion and surface smoothness. Tests have shown that coating systems containing KF-54 achieve over 20% improvements in gloss and wear resistance, meeting the demands of high-end industrial and decorative applications.

Rubber and Plastic Molding - KF-54 is widely used in the release process for rubber and plastic molds. Its low surface tension and chemical inertness effectively reduce mold residue and shorten production cycles. Data show that after 500 consecutive molding cycles, the mold surface remains free of noticeable contamination, and the surface integrity of the molded product remains high, significantly improving mold life and production efficiency.

Automotive Industry - In automotive manufacturing, KF-54 is used to lubricate and protect high-temperature components. Its high-temperature resistance and low volatility ensure long-term operational stability for engines and exhaust systems. In actual application testing, engine components maintained a good lubricating film even after 2,000 hours of continuous operation at 200°C, significantly reducing wear and improving vehicle durability.