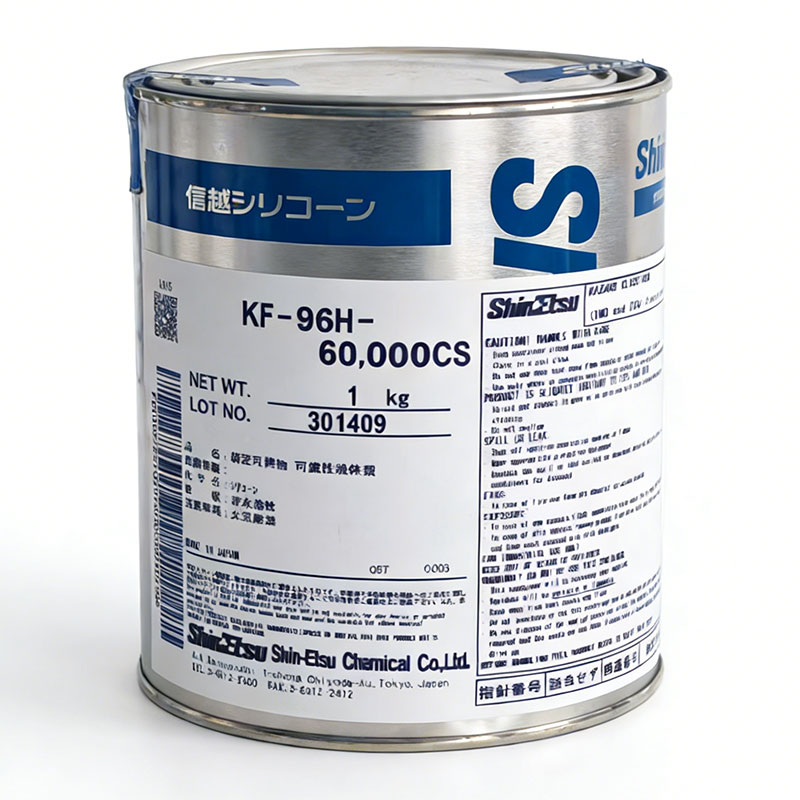

ShinEtsu KF-96H-60000cs - PDMS Silicone Oil Main Cosmetic Material for Skincare, Makeup & Lotion

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

Shin-Etsu KF-96H-60000cs is a clear, high-purity polydimethylsiloxane (PDMS) engineered to provide superior damping and surface protection. As a specialized mechanical buffer fluid, it maintains consistent viscosity under high shear and temperature fluctuations, making it the industry standard for shock absorber oil applications. Its high molecular weight ensures a thick, protective film that excels in heavy-duty industrial environments.

Products parameters

| Composition: | Dimethylpolysiloxane (PDMS) |

| Appearance: | Clear Transparent Liquid |

| Viscosity 25 °C mm²/s: | 60,000 mm²/s |

| Refractive Index At 25 °C: | ~1.403 |

| Flash Point: | 315 min |

| Packaging: | 18kg, 200kg |

Key features

Superior Damping Properties – Functions as a high-performance mechanical buffer fluid, providing excellent vibration and noise reduction in precision instruments.

Heavy-Duty Mold Release – Acts as a specialized heavy-duty rubber molding release agent, ensuring clean de-molding of complex parts without surface defects.

Exceptional Shear Stability – Engineered as a reliable shock absorber oil, maintaining its 60,000 cSt viscosity even under intense mechanical pressure.

High-Build Barrier Protection – Serves as a 60k cSt dimethicone for personal care, imparting a luxurious, water-resistant film for long-lasting skin and hair protection.

Thermal and Chemical Resistance – Utilized as a synthetic fiber lubricant and industrial thickening agent that remains stable against oxidation and extreme temperatures.

Automotive & Aerospace – Applied as a primary shock absorber oil and mechanical buffer fluid in damping systems to enhance vehicle stability and comfort.

Rubber & Plastic Manufacturing – Used as a heavy-duty rubber molding release to facilitate high-volume production of industrial gaskets, seals, and tires.

Personal Care & Cosmetics – Formulated as a 60k cSt dimethicone for personal care in intensive hair masks and barrier creams for a smooth, non-greasy finish.

Textile Processing – Integrated into manufacturing as a synthetic fiber lubricant to reduce yarn breakage and improve high-speed processing efficiency.

Lubricant Customization – Utilized as an industrial thickening agent to increase the consistency and load-bearing capacity of specialized silicone greases.