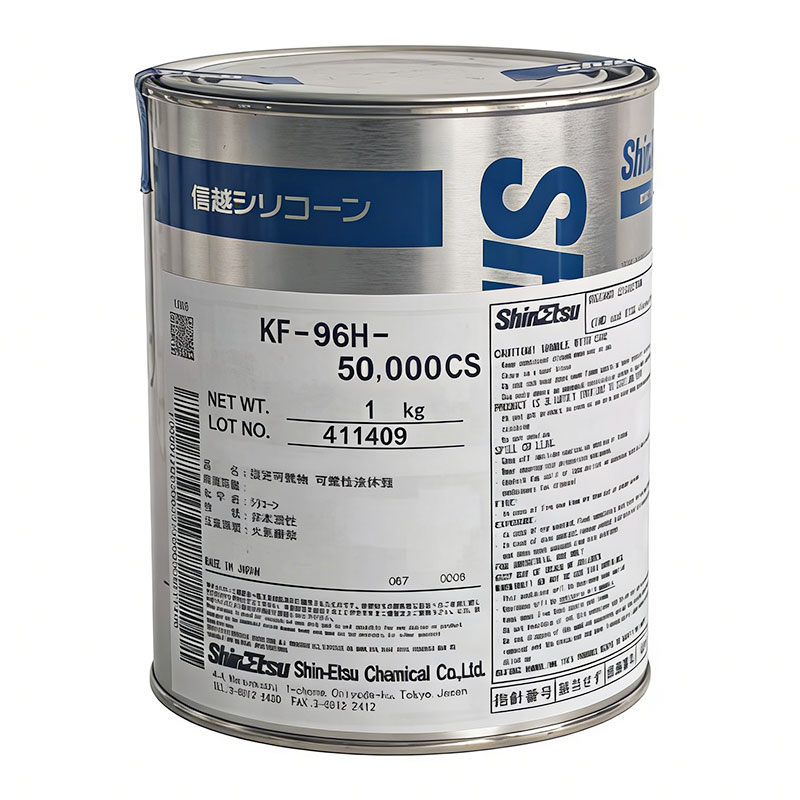

ShinEtsu KF-96-50000cs - Silicone Oil Defoamer and Metering Pump Piston Lubricant & Damping Grease

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

The Shin-Etsu KF-96-50000cs is a high-purity, linear dimethyl silicone oil (PDMS) engineered for applications demanding a robust, long-lasting barrier. Its high 50,000 cSt viscosity ensures excellent surface coverage and film strength, making it an indispensable heavy-duty rubber molding release agent that prevents material sticking and reduces residue buildup.

Products parameters

| Composition: | Dimethylpolysiloxane (PDMS) |

| Appearance: | Clear Transparent Liquid |

| Viscosity 25 °C mm²/s: | 50,000 mm²/s |

| Refractive Index At 25 °C: | ~1.403 |

| Flash Point: | 315 min |

| Packaging: | 18kg, 200kg |

Key features

Superior High-Viscosity Release – Functions as a robust high-viscosity mold release agent, ideal for complex polymer and rubber parts with deep draws or intricate designs.

Heavy-Duty Performance – Acts as a reliable heavy-duty rubber molding release, ensuring clean separation and minimizing downtime in high-volume manufacturing.

Textile Processing Aid – Used as an efficient synthetic fiber lubricant, improving processability and imparting desirable softness and antistatic properties to fabrics.

Thermal Stability – Maintains consistent performance and lubricity across a wide temperature range, resisting breakdown and oxidation in hot molding environments.

Subtle Optical Properties – While an industrial fluid, its high refractive index can impart a slight soft-focus blurring effect when formulated into certain coatings or sealants.

Rubber Manufacturing – Primarily used as a heavy-duty rubber molding release agent for tires, O-rings, and automotive rubber components.

Plastics & Composites – Applied as a high-viscosity mold release for challenging plastic injection molding and composite material production.

Textile Industry – Integrated as a synthetic fiber lubricant during spinning and weaving processes to reduce friction and improve fiber quality.

Mechanical Damping – Utilized in specific instruments as a high-viscosity fluid for consistent damping and motion control.

Industrial Finishes – Used as a specialty additive in certain non-cosmetic coatings where a slight soft-focus blurring effect on the surface finish is desired for visual masking.