ShinEtsu KE-24 – RTV II Condensation Cure Silicone Rubber for Molding and Casting

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

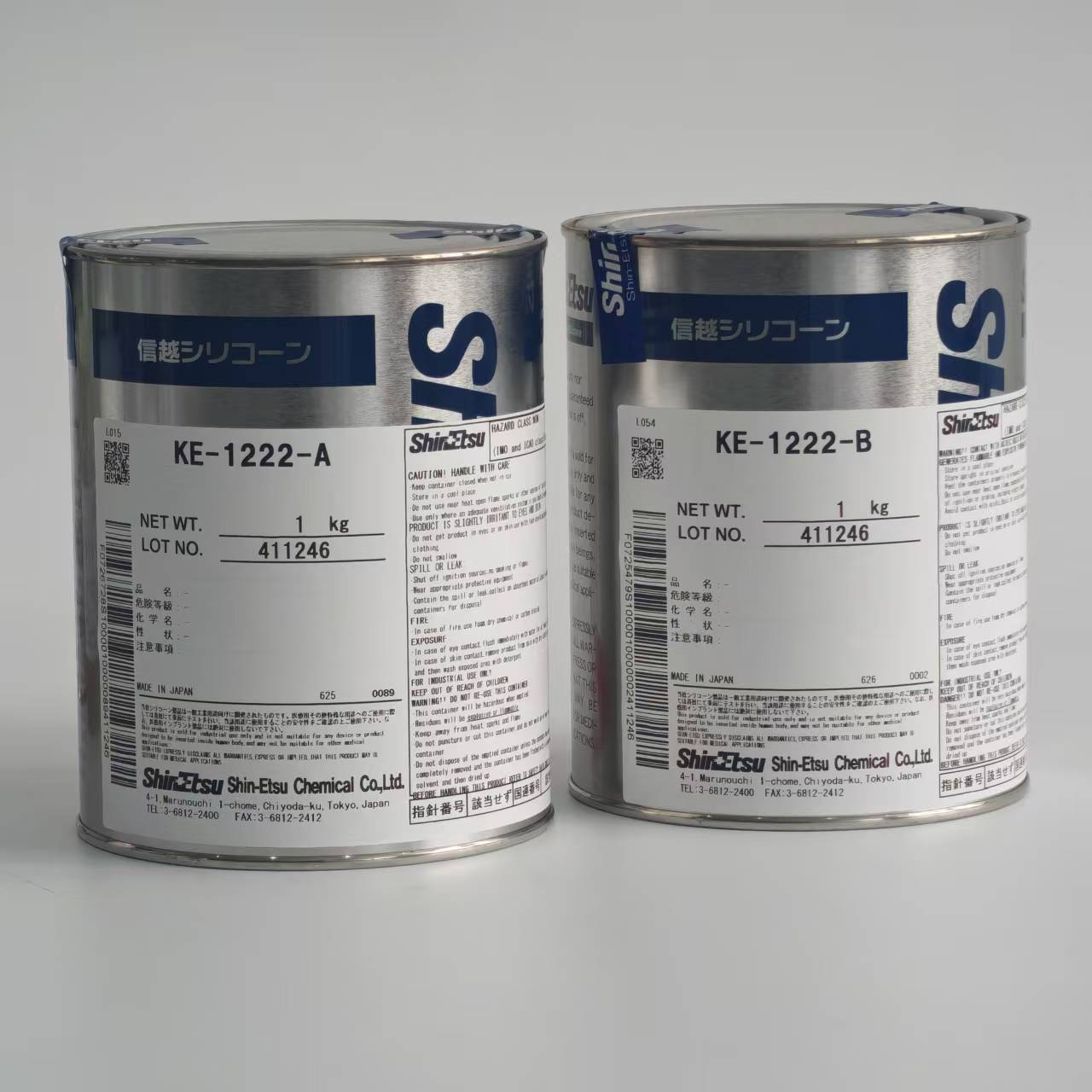

KE-24 is a two-part condensation-cure RTV silicone rubber developed for room-temperature mold making and casting operations that require repeated use and stable reproduction accuracy. Supplied as a base component with a curing agent, it is mixed prior to use and flows smoothly into molds, allowing users to capture fine details with controlled handling behavior. During curing, KE-24 transitions evenly into a flexible elastomer, providing a predictable working experience and reliable demolding performance across multiple casting cycles.

products parameters

| Composition: | Two‑part RTV Silicone Rubber |

| Appearance: | Viscous Liquid |

| Cure System: | Condensation (moisture Cure) |

| Specific Gravity: | ~1.12 |

| Packaging: | 1kg |

key features

Material Durability - KE-24 cures into a robust silicone elastomer designed to withstand repeated casting cycles without rapid degradation. Typical tear strength values exceed 20 kN/m, supporting resistance to mechanical stress during demolding. Under standard operating conditions, molds produced with KE-24 can maintain dimensional stability across dozens of casting cycles, reducing replacement frequency and material waste.

Release Performance - KE-24 exhibits low surface energy after cure, enabling effective release from a wide range of casting materials. Demolding force measurements are typically reduced by more than 30 percent compared with conventional rubber molds without release aids. This performance supports clean separation from resin, plaster, and metal surfaces while preserving mold detail accuracy.

Elastic Recovery - After curing, KE-24 maintains consistent elasticity that supports precise reproduction of complex geometries. Typical elongation at break exceeds 350 percent, while Shore A hardness commonly falls within the 25 to 35 range. These values allow the mold to flex during part removal and recover its original shape without permanent deformation.

Chemical Resistance - KE-24 demonstrates stable resistance to common casting resins and industrial chemicals. Weight change after 72 hours of exposure to standard epoxy or polyurethane resins typically remains below 1 percent. This resistance helps maintain mold integrity when exposed to reactive casting systems over extended production runs.

Resin Casting - KE-24 is used for producing silicone molds for resin casting processes where surface detail and repeatability are required. Mold thicknesses of 10 to 30 mm can cure evenly at room temperature, supporting stable mold walls. The cured silicone enables consistent replication of fine textures across multiple resin pours.

Plaster Casting - In plaster and gypsum casting, KE-24 supports smooth mold filling and clean demolding. Its elasticity allows easy removal of rigid plaster parts without chipping or mold damage. Dimensional variation in repeated casts is typically controlled within tight tolerances, supporting uniform production output.

Metal Casting - KE-24 is applied in low-temperature metal casting processes where flexible molds are required. The cured silicone maintains structural integrity when exposed to molten alloys within compatible temperature ranges. This supports repeated use in prototype or short-run metal casting applications.

Industrial Tooling - In industrial tooling and prototyping, KE-24 is used to create durable molds for repeated part production. Its balance of strength and flexibility supports consistent mold geometry over time. This reliability helps reduce tooling downtime and supports efficient small-batch manufacturing workflows.