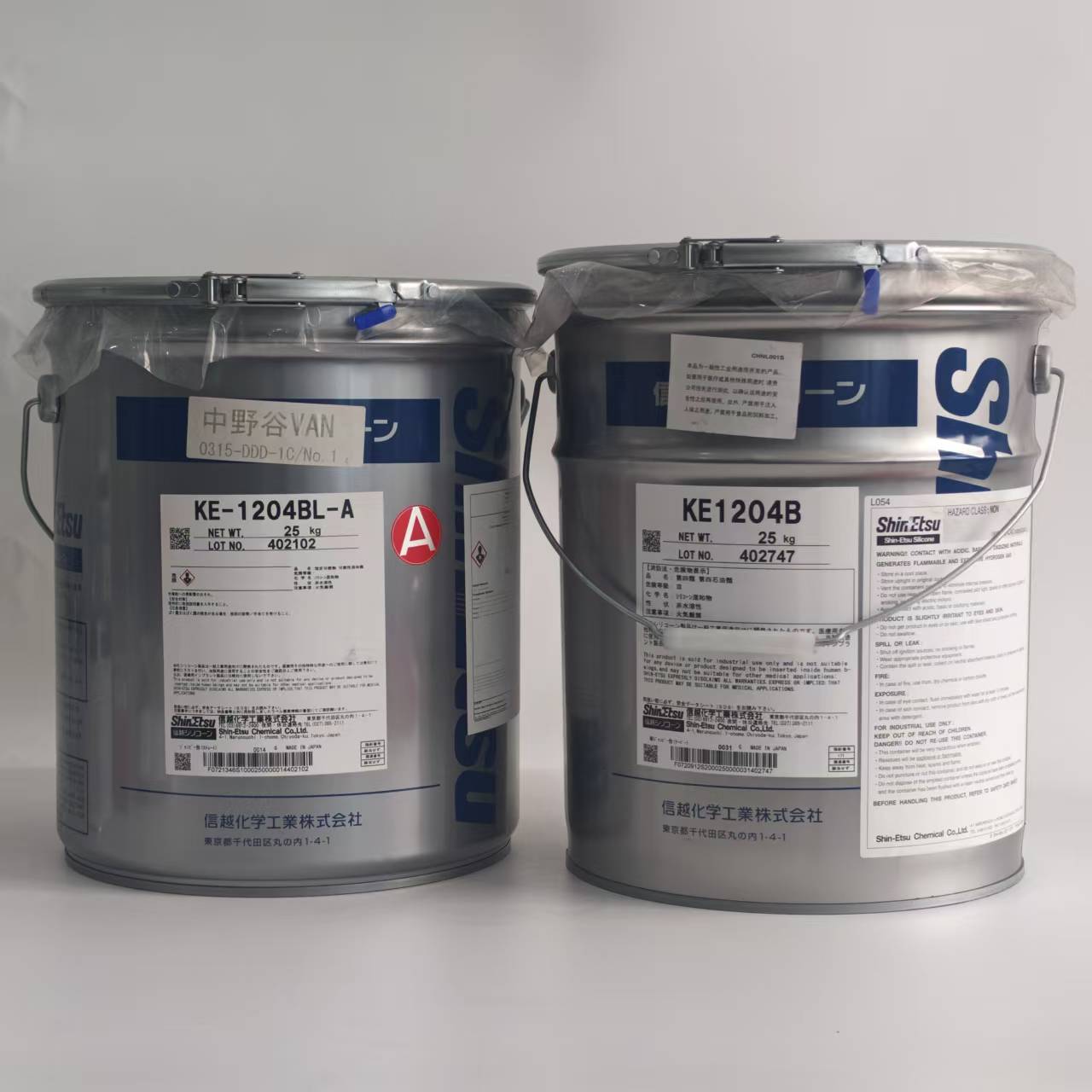

ShinEtsu KE-1204A/B - Two-Component RTV Silicone for Potting and Encapsulation

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-1204 A/B is a two-component, room-temperature curing silicone potting material designed for encapsulating and protecting electronic and electrical components. It consists of a red component (A) base material and a white component (B) curing agent, mixed in a 1:1 weight ratio. It cures rapidly at room temperature to form an elastomer with high hardness and excellent stability. The cured material exhibits excellent insulation, moisture resistance, and thermal shock resistance, effectively resisting vibration and thermal stress, ensuring the long-term reliable operation of electronic components.

products parameters

| Appearance: | Part A – Base (red), Part B – Curing Agent (white) |

| Mixing Ratio: | 1:1 (by Weight) |

| Viscosity(at 25°C): | Part A – 60, Part B – 40 |

| Hardness: | 70 Shore A |

| Temperature Resistance: | -55°C To 250°C |

| Packaging: | 2 Kg Set, 50kg Set |

key features

High Temperature Resistance - After curing, KE-1204 A/B can withstand temperatures ranging from -55°C to 250°C for extended periods, with intermittent temperature resistance reaching up to 260°C. In thermal cycling tests, samples maintained a hardness retention exceeding 90% after 1,000 cycles from -40°C to 200°C.

Fast Curing - This material exhibits rapid curing properties, achieving initial cure within tens of minutes at room temperature after mixing and fully cross-linking within 24 hours. This shortened curing time improves production efficiency. At 25°C, it achieves a hardness of 70 Shore A with stable strength, ensuring consistent and efficient component production in mass production.

Precise Mixing - KE-1204 A/B is mixed in a 1:1 weight ratio, eliminating complex ratio calculations and metering errors. Experiments have shown that when the mixing tolerance is controlled within ±5%, the curing and mechanical properties remain stable. This advantage significantly improves ease of use and process stability, reducing operator dependence on equipment accuracy.

Heat Curing - While KE-1204 A/B cures at room temperature, heat curing at 80°C to 120°C significantly shortens the cure time and increases the crosslink density. Testing shows that heat curing increases the tensile strength by approximately 18% and the volume resistivity by up to 10¹⁵ Ω·cm, further enhancing the material's insulation performance and durability.

Self-Leveling - KE-1204 A/B exhibits excellent self-leveling properties, allowing them to evenly fill small gaps and complex surface structures after mixing. Viscosity data shows that component A has a viscosity of 60 Pa·s at 25°C, while component B has a viscosity of 40 Pa·s. This low-to-medium viscosity ensures fluidity and film-forming properties, resulting in a smooth, even potting layer without the need for additional finishing or treatment.

Electronics and Electrical - KE-1204 A/B is widely used in the electronics and electrical industries for potting and protecting circuit boards, modules, and sensitive components. Its high dielectric strength and excellent insulation properties prevent arcing and breakdown. Experiments have shown that after a 2000-hour high-temperature, high-humidity test at 85°C/85%RH, the insulation resistance retention exceeded 92%, effectively improving the reliability and lifespan of electronic products.

Power Control - In power electronics and control systems, KE-1204 A/B is used for sealing and protecting power modules, inverters, and rectifiers. Its high-temperature and thermal shock resistance ensures stable operation of power devices under high-load conditions. Thermal cycling test data shows no signs of cracking in the device housing or internal structure after 500 continuous cycles from -55°C to 250°C.

Communications Systems - KE-1204 A/B is primarily used in communications and transmission systems for potting RF modules, antennas, and signal amplifiers. Its moisture resistance ensures stable operation in high-humidity environments. Test results show that after 1000 hours of salt spray testing, the increase in signal transmission loss was less than 3%, effectively preventing environmental factors from affecting communication quality.

Automotive Electronics - In the automotive electronics field, KE-1204 A/B can be used for potting and protecting sensors, control units, and lighting modules. Its shock resistance and high-temperature resistance make it suitable for the complex environment of the engine compartment. Road simulation tests showed that after 800 hours of vibration and temperature cycling, the potting layer remained intact, with no cracking or delamination.