ShinEtsu KE-12 – RTV I Adhesive Sealant for General Bonding and Sealing

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-12 is a one-part condensation-cure RTV silicone rubber designed for room-temperature sealing and bonding applications. It is supplied as a ready-to-use paste that does not require mixing, allowing users to apply it directly from the container with consistent flow and handling behavior. During curing, KE-12 reacts with ambient moisture and gradually transforms into an elastic rubber, providing a stable and predictable user experience suitable for routine sealing operations and general-purpose industrial use.

products parameters

| Composition: | One‑Part RTV Silicone |

| Appearance: | Paste |

| Cure System: | Condensation (moisture Cure) |

| Specific Gravity: | ~1.02 |

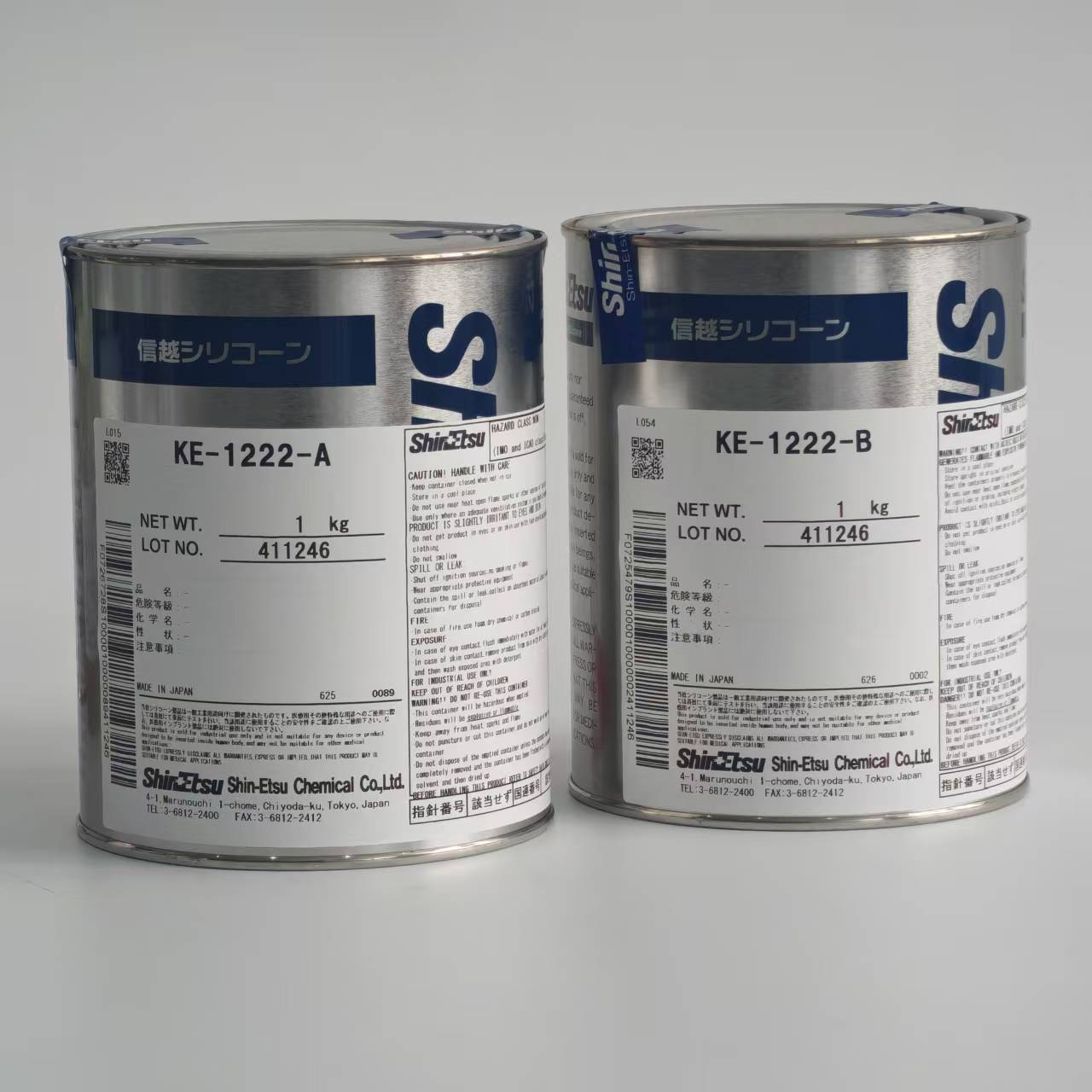

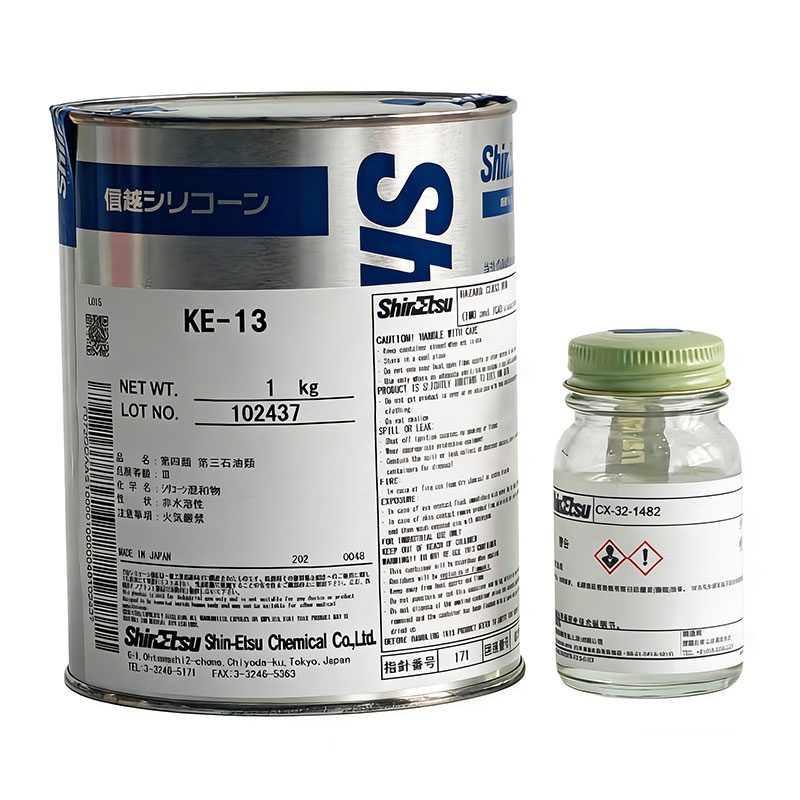

| Packaging: | 1kg |

key features

Easy to Use - KE-12 is a one-part RTV silicone that eliminates the need for proportioning or mixing before application. This structure reduces application errors and improves consistency across operators. In practical use, curing begins upon exposure to air moisture, with surface skin formation typically occurring within 10–20 minutes at 23 °C and 50% relative humidity, supporting efficient workflow control.

Moisture Resistant - KE-12 cures through a condensation mechanism driven by ambient humidity, enabling reliable curing under normal environmental conditions. At standard conditions of 23 °C and 50% relative humidity, a curing rate of approximately 2–3 mm per 24 hours is commonly achieved. This predictable cure depth supports controlled sealing thickness and stable bond development over time.

Elastic Retention - After full cure, KE-12 maintains long-term elasticity suitable for movement and vibration compensation. Typical elongation at break can exceed 300%, allowing cured joints to absorb mechanical displacement without cracking. Shore A hardness generally remains in the range of 20–30, supporting flexible sealing performance over extended service periods.

Wide Adhesion Range - KE-12 exhibits reliable adhesion to common substrates without the need for primers in many cases. Typical adhesion strength to materials such as glass, aluminum, and ceramic substrates can reach 0.5–1.0 MPa under standard test conditions. This adhesion consistency supports dependable bonding performance in routine sealing tasks.

Construction Sealing and Bonding - KE-12 is used in construction environments for sealing joints and gaps exposed to ambient conditions. Its moisture-curing behavior allows it to cure effectively on-site without controlled heating. Typical joint widths of 5–15 mm can be sealed effectively, supporting weather resistance and long-term joint integrity in building assemblies.

Electronics Protection - In electronics-related sealing, KE-12 is applied as a moisture barrier to protect components from humidity ingress. Once cured, silicone layers typically maintain stable insulation behavior with volume resistivity above 10¹³ Ω·cm. This supports the protection of connectors, housings, and non-heat-sensitive electronic assemblies.

Automotive Gasketing - KE-12 is suitable for forming elastic gaskets in automotive assemblies where vibration and thermal cycling are present. Its cured elasticity allows compensation for joint movement while maintaining sealing continuity. Typical service temperature tolerance supports operation from approximately –50 °C to 180 °C, meeting common automotive sealing demands.

Industrial Sealing - In general industrial sealing applications, KE-12 is used to seal equipment housings, panels, and enclosures. Its paste consistency allows controlled bead application on vertical and horizontal surfaces. Stable curing behavior supports repeatable sealing quality across maintenance and assembly operations.