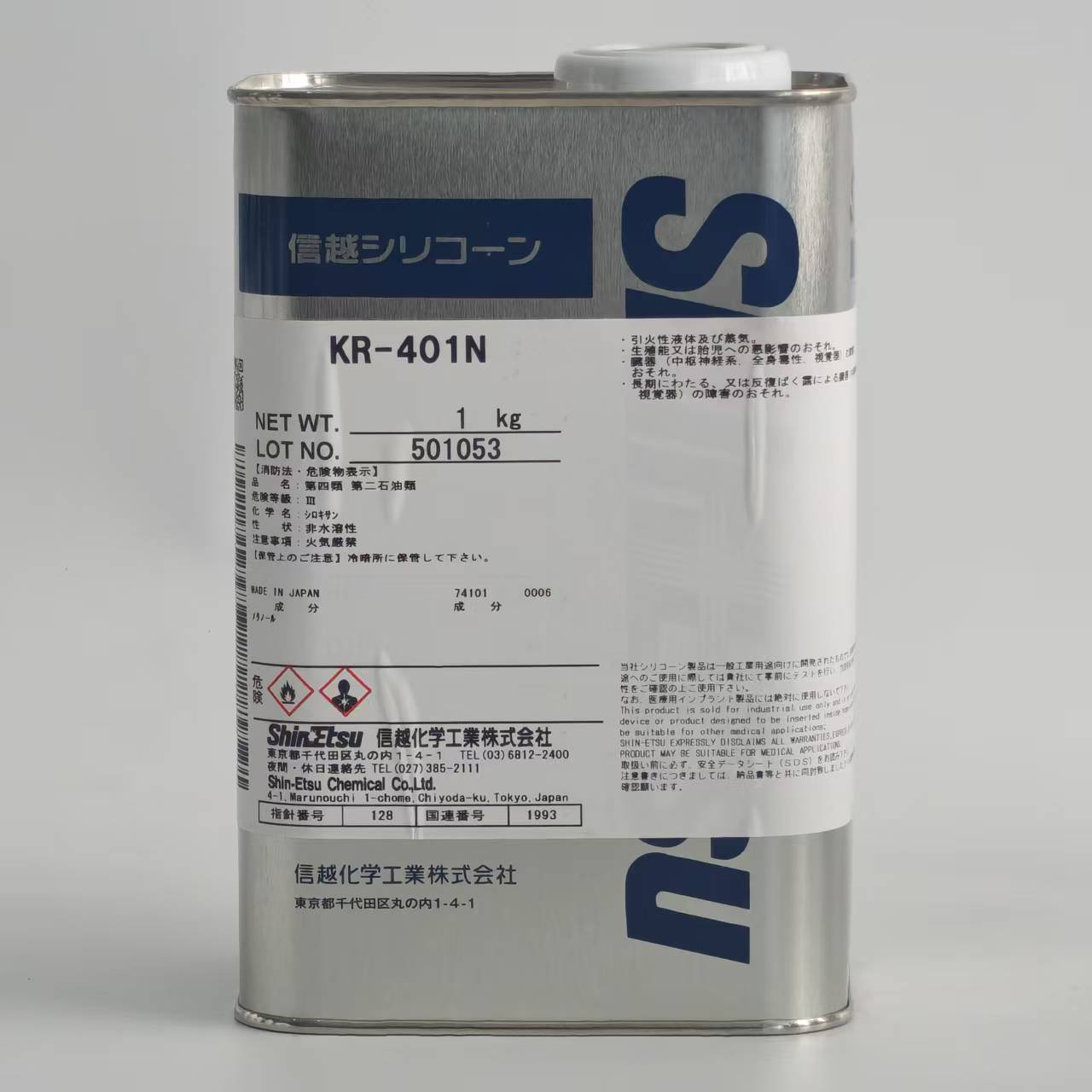

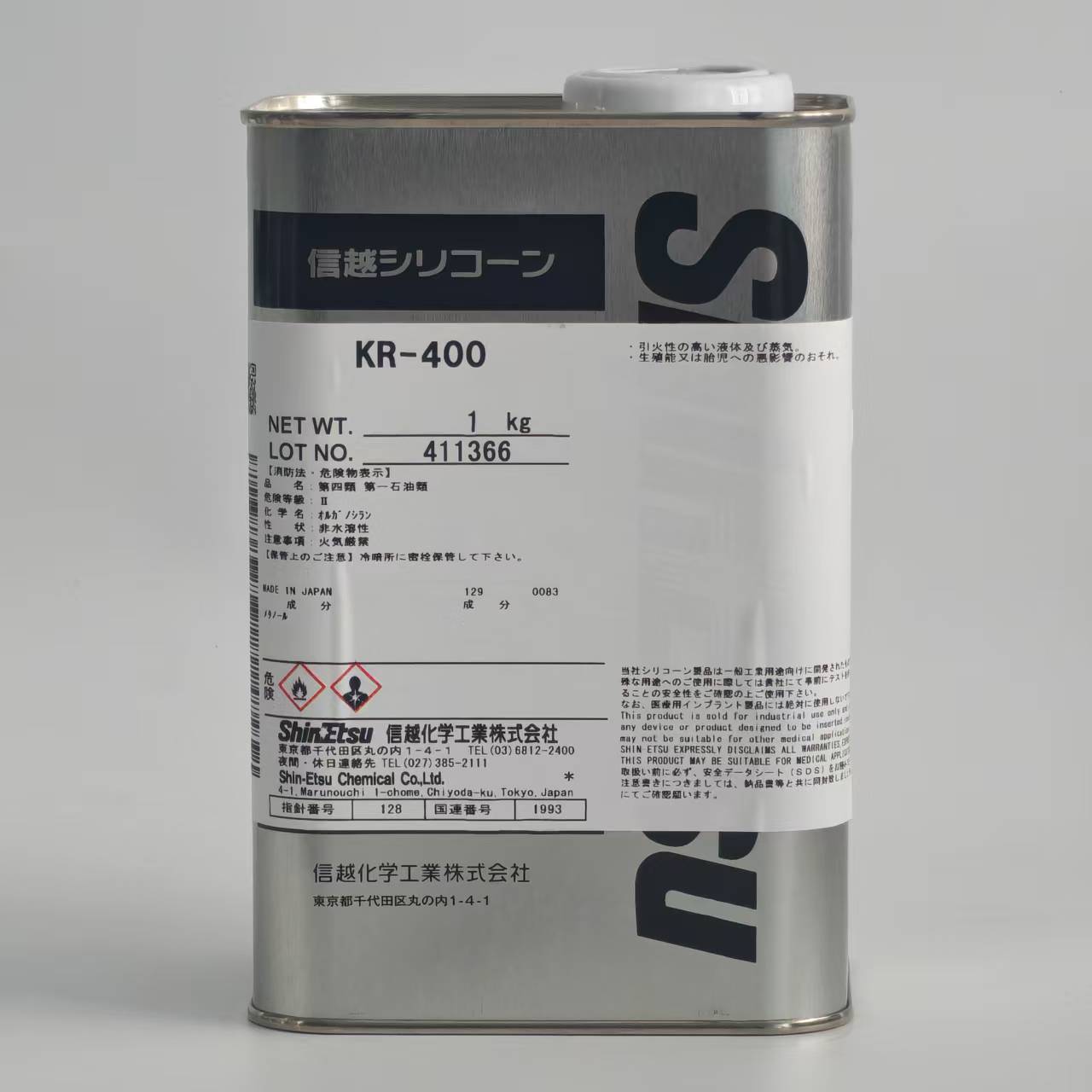

ShinEtsu KR-400 - Silicone Resin Coating for Automotive And Industrial Surfaces

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KR-400 is designed for high-hardness coatings. It provides excellent transparency, durability, and resistance to heat, weathering, and chemicals, making it ideal for automotive finishes, floor coatings, and industrial protective applications. It also protects automotive paint from water, dust, and UV damage.

PRODUCTS PARAMETERS

| Composition: | Colourless To Pale Yellow Transparent Liquid |

| Kinematic Viscosity: | ~1.2 Mm²/s |

| Refractive Index: | 1.390 |

| Packaging: | 1kg |

key features

High-Temperature Resistance - KR-400 exhibits excellent high-temperature resistance, maintaining stable structure and performance at 250°C. Experiments show that after 500 hours of continuous treatment at 250°C, surface hardness and gloss retention exceed 90%, and the thermal decomposition temperature exceeds 300°C, demonstrating its long-term protection in high-temperature environments.

UV Resistance - KR-400 exhibits excellent resistance to UV rays. In UV aging tests, after 1000 hours of exposure to 340nm UV light, the coating's yellowing index (ΔYI) was less than 2, and gloss retention exceeded 88%, demonstrating its ability to maintain transparency and color stability in long-term outdoor environments, preventing degradation caused by light.

High Hardness - KR-400 significantly improves the surface hardness of coatings, protecting substrates from mechanical damage. Pencil hardness tests show that coatings modified with KR-400 can achieve a hardness of H or higher, over 30% higher than unmodified samples, effectively reducing scratches and abrasion marks and extending product life.

Excellent Hydrophobicity - KR-400 exhibits excellent hydrophobic properties, forming a stable hydrophobic film. Contact angle testing shows that the static contact angle of a water droplet on the KR-400 coating exceeds 105°. KR-400 maintains excellent surface protection even in hot and humid environments, significantly reducing the risk of water penetration and improving the coating's overall weather resistance.

Electrical Insulation - KR-400 exhibits excellent dielectric properties. At 25°C, its dielectric constant is 2.8, its dielectric strength reaches 25 kV/mm, and its volume resistivity exceeds 1×10¹⁴ Ω·cm. These data demonstrate that KR-400, when used as a surface coating on electrical equipment, effectively prevents leakage and short circuits, ensuring reliable operation.

Automotive Industry - KR-400 is widely used in automotive coatings, particularly for high-hardness clearcoats on vehicle bodies. Actual testing shows a 25% improvement in salt spray resistance. After a 720-hour salt spray test, the paint film showed no noticeable gloss loss or blistering, ensuring long-term resistance to road corrosion and UV damage.

Electronic and Electrical Industry - KR-400 can be used as a protective coating in electronic and electrical equipment, providing insulation and aging resistance. Experiments have shown that electrical components coated with KR-400 maintain an insulation resistance of over 10¹³ Ω·cm after 1000 hours under high-temperature and high-humidity conditions at 85°C and 85% RH, meeting the requirements for long-term stable operation.

General Industry - KR-400 is suitable for protective coatings on mechanical parts, extending their service life. Friction and wear tests showed that the mass loss of the coated sample after 10,000 reciprocating friction cycles was less than 2%, demonstrating significant wear resistance and effectively reducing maintenance costs for industrial equipment.

Chemical Industry - KR-400 protects chemical equipment surfaces from corrosion caused by strong acids and alkalis. Chemical immersion tests showed that after 72 hours of immersion in a 10% sulfuric acid and 10% sodium hydroxide solution, the coating showed no noticeable gloss loss or cracking, and its quality retention rate exceeded 98%, demonstrating its excellent chemical stability.

Coatings Industry - KR-400 can be used as a high-performance coating additive to improve transparency and leveling. Experimental data showed that adding 1wt% KR-400 reduced film haze by 40% and increased gloss by 15%, resulting in a more uniform visual effect in industrial flooring and decorative coatings.

Cosmetics Industry - In cosmetic formulations, KR-400 can be used as a functional coating ingredient to enhance product durability and gloss. Skin compatibility testing confirmed that the KR-400 film-forming system is non-irritating to the skin and maintains a transparent protective film for over 8 hours, enhancing the protective properties of cosmetics and the user experience.