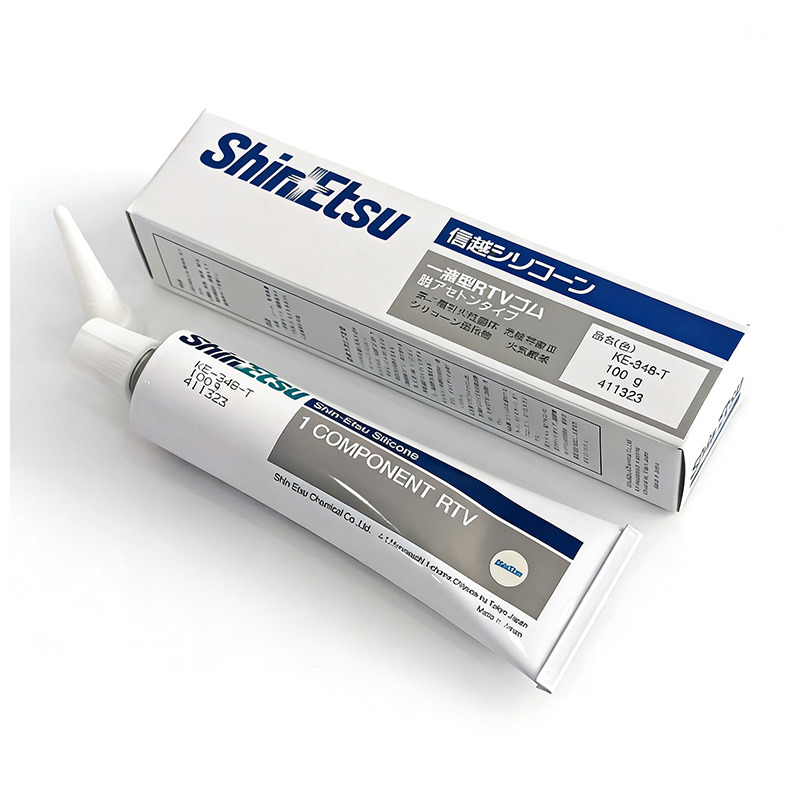

ShinEtsu KE-348 – General Purpose Silicone Rubber for Industrial Sealing & Molding

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-348 is a two-component RTV silicone rubber designed for general industrial use, supplied as a viscous liquid system that is mixed prior to application. During use, it offers smooth mixing behavior, stable flow, and controlled leveling, allowing users to handle casting, sealing, or molding tasks with predictable processing response. As curing progresses at room temperature, KE-348 transitions evenly into an elastomer with consistent surface quality, providing a stable and reliable user experience across routine industrial operations.

products parameters

| Composition: | Silicone Rubber |

| Colour: | White, Translucent |

| Appearance: | Viscous Liquid |

| Specific Gravity (25 °C): | ~1.12 |

| Refractive Index (25 °C): | ~1.410 |

| Packaging: | 100g, 330ml |

key features

General Grade - KE-348 is formulated as a general-purpose two-part RTV silicone rubber with stable processing characteristics. At 25 °C, its typical viscosity is approximately 12,000 mm² per second, allowing smooth pouring and controlled flow without excessive spreading. This viscosity range supports consistent handling during sealing, molding, or casting preparation steps.

Mechanical Balance - After full cure, KE-348 achieves a balanced mechanical profile suitable for repeated deformation. Typical tensile strength ranges from 3.0 to 4.0 MPa, while elongation at break commonly exceeds 200 percent. This balance allows the cured elastomer to absorb mechanical stress and recover shape without cracking under routine industrial loads.

Elastic Recovery - KE-348 maintains stable elastic recovery after repeated deformation cycles. Shore A hardness typically falls within the range of 25 to 35, supporting controlled flexibility without excessive softness. Compression set values are generally below 30 percent after 24 hours at elevated temperature, indicating reliable shape recovery performance.

Chemical Resistance - The cured elastomer shows resistance to common industrial fluids such as mineral oils and lubricants. Weight change after 72 hours of immersion in standard industrial oils typically remains below 1 percent. This resistance helps preserve both mechanical integrity and surface condition during prolonged chemical exposure.

Thermal Stability - KE-348 maintains consistent mechanical performance under moderate thermal conditions. Typical service temperature range extends from approximately −40 °C to 150 °C, with tensile strength retention above 80 percent after thermal aging tests. This stability supports reliable elastomer behavior during temperature fluctuations in industrial environments.

Industrial Sealing - KE-348 is used for sealing joints and interfaces in industrial equipment. Seal thicknesses of 3 to 10 mm can cure evenly at room temperature. The cured elastomer maintains flexibility under operational vibration and temperature variation, supporting long-term sealing reliability.

Mold Making - In mold-making processes, KE-348 supports accurate reproduction of parts with moderate detail requirements. Its controlled flow allows uniform mold filling without excessive air entrapment. The cured silicone provides sufficient flexibility for repeated demolding operations.

Casting Support - KE-348 is applied in casting processes where stable elastomer formation is required. Typical casting sections of 10 to 25 mm can cure uniformly under ambient conditions. This supports consistent part geometry across multiple production cycles.

Potting Tasks - In general potting operations, KE-348 provides mechanical support and environmental isolation for components. The cured material distributes stress evenly around embedded parts. This helps reduce mechanical strain caused by vibration or handling.

General Manufacturing - KE-348 is also used in general manufacturing processes requiring a reliable silicone elastomer. Its predictable curing behavior supports repeatable results in small-batch or routine production. This consistency helps reduce process variability and rework rates.