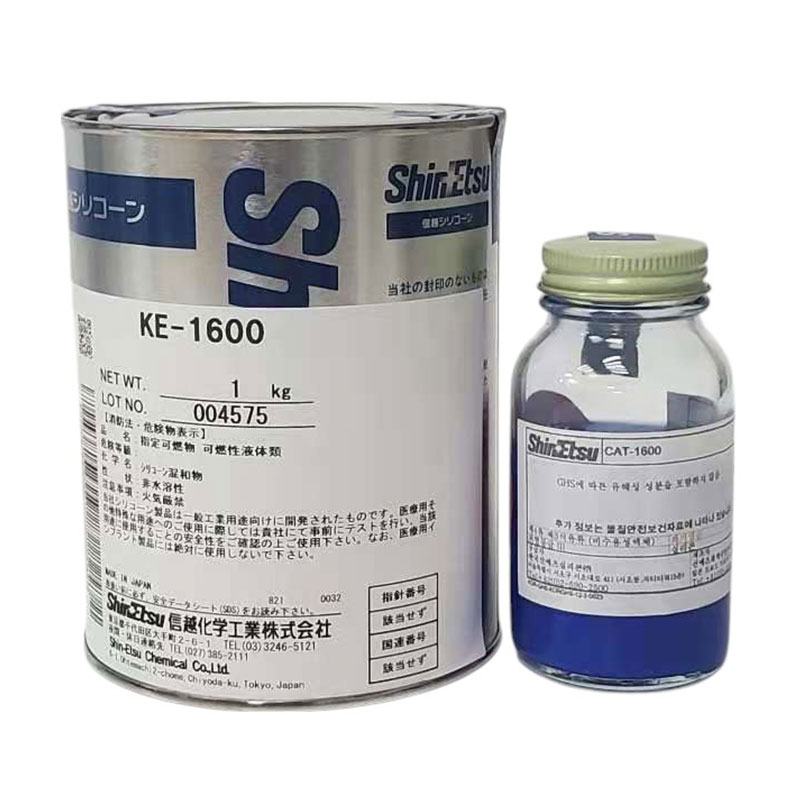

ShinEtsu KE-1606 - Two-Component Silicone Rubber for Moldmaking

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-1606 is a high-performance adhesive sealant developed for demanding industrial, electronic, and construction applications. It delivers excellent adhesion to a wide range of materials, including metals, plastics, ceramics, glass, and concrete. KE-1606 is designed to maintain stable performance in challenging conditions, offering exceptional weather resistance, electrical insulation, and long-term durability. Once cured, it forms a strong yet flexible seal that resists cracking, aging, and shrinkage. This makes it a dependable choice for electronics sealing, construction joints, and automotive assembly.

products parameters

| Composition: | Silicone Rubber |

| Appearance: | Transparent |

| Viscosity: | 60 |

| Density: | 1.03(After Curing) |

| Mix Ratio: | 10:01 |

| Packaging: | 1.1kg |

key features

Strong Bonding - After curing, KE-1606 exhibits excellent bonding properties, providing excellent adhesion to metals, plastics, ceramics, glass, and concrete. Bond strength testing shows a shear strength of 2.0 MPa on steel and a peel force exceeding 0.8 N/mm on aluminum, ensuring structural components maintain a secure bond despite vibration and stress, reducing the risk of rework and failure.

Weather Resistance - KE-1606 remains stable in environments exposed to alternating high and low temperatures, UV radiation, and fluctuating humidity. After 500 cycles of testing from -40°C to 180°C, the material's performance degradation rate was less than 5%. Furthermore, after 1000 hours of UV irradiation, its surface showed no visible cracking or chalking, demonstrating its excellent weather resistance and suitability for outdoor use and harsh working conditions.

Electrical Insulation - KE-1606 boasts high dielectric strength, with an electrical breakdown strength exceeding 20 kV/mm, effectively preventing the risks of short circuits and arcing. When used in humid and dusty environments, the material provides significant protection for electronic components, blocking moisture and fine particles, ensuring long-term stable operation of electrical equipment and enhancing system safety.

Flexible and Durable - The sealant formed by KE-1606 after curing exhibits excellent elasticity and flexibility. Its hardness remains in the Shore A range of 40-45, and after 10,000 cycles, its compression set remains below 8%.

Versatile - KE-1606's formulation ensures its adaptability across a wide range of industries. Its easy application, 10:1 mix ratio, and 1.1 kg packaging facilitate its use in production lines of varying sizes.

Electronics Industry - KE-1606 is widely used in the electronics industry for sealing circuit boards and encapsulating components. Its electrical insulation strength exceeds 20 kV/mm, effectively preventing leakage and breakdown in high-voltage environments. KE-1606 also provides a protective barrier in humid and dusty environments, extending the life of electronic components and ensuring product stability.

Automotive Industry - KE-1606 is used to seal seams and secure components during automotive assembly. Its temperature resistance range extends from -40°C to 180°C, allowing it to withstand both the high temperatures of the engine compartment and the impact of low temperatures outside. In aging tests, the material maintained over 90% of its bond strength after 1,000 hours of continuous operation at high temperatures, meeting automotive longevity requirements.

Industrial Equipment - Industrial equipment operates under high loads and high humidity, placing stringent sealing requirements. KE-1606's weather and chemical resistance make it suitable for sealing pumps, valves, and motors. Test data shows no noticeable damage to the sealing layer after 2,000 hours of continuous operation, effectively reducing the frequency of equipment downtime and maintenance.

Home Appliance Industry - In home appliance manufacturing, KE-1606 can be used to seal electrical components against moisture and dust. Its transparent appearance ensures aesthetically pleasing assembly, while its electrical insulation strength exceeds 20 kV/mm, preventing short circuits. The material exhibits excellent stability in applications such as refrigerators and washing machines subject to long-term humid environments.

Construction Industry - In the construction industry, KE-1606 is commonly used for sealing expansion joints, door and window joints, and curtain wall systems. Its UV and humidity resistance has been tested and has maintained excellent sealing performance and bond strength even after five years of outdoor exposure, ensuring the safety and durability of building structures and significantly reducing maintenance costs.