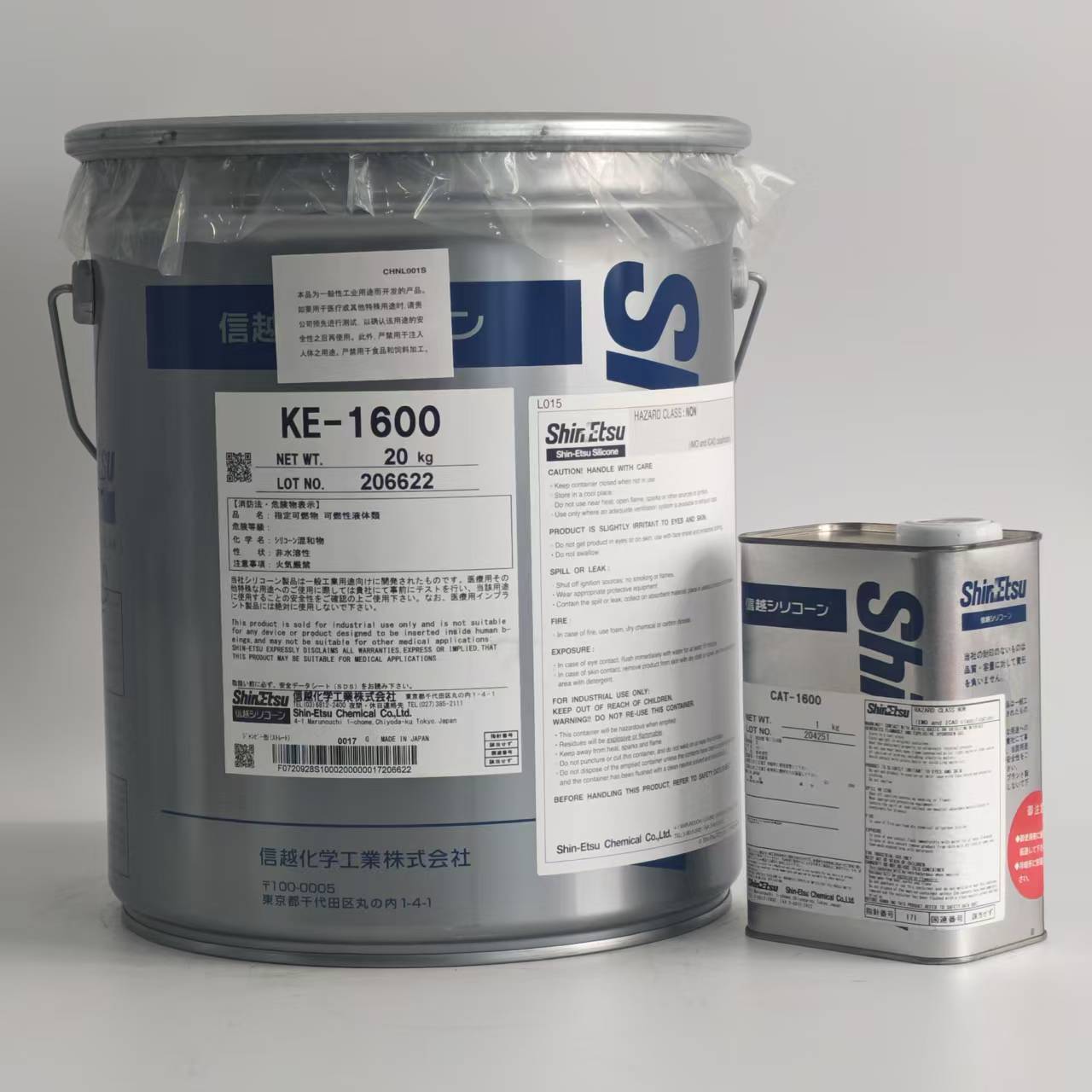

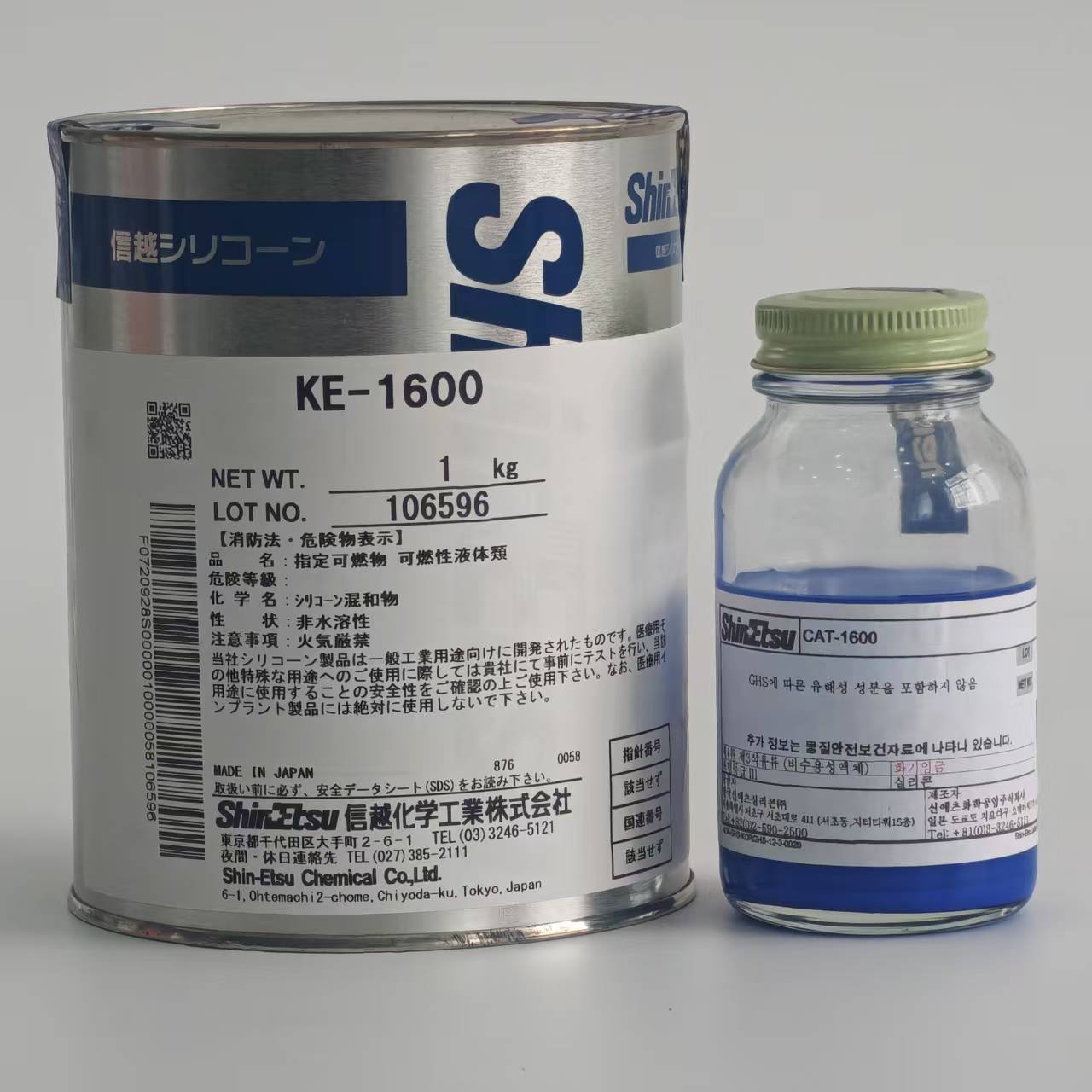

ShinEtsu KE-1600 - High-Strength Rubber for Potting Adhesive

-

+852 9408 1652 WhatsApp

-

info@innosiltech.com Email

KE-1600 is a two-component silicone rubber that cures blue and is designed for molds made of polyurethane foam and other organic resins. Its excellent tear strength, low shrinkage, and high hardness ensure mold stability and reliability over long-term use. KE-1600's low cost and long mold life provide users with a cost-effective experience. Its excellent mold release and heat resistance also reduce maintenance requirements during production.

products parameters

| Composition: | Silicone Rubber |

| Appearance: | Blue(After Curing) |

| Density: | 1.27(After Curing) |

| Mix Ratio: | 10:01 |

| Packaging: | 1.1kg & 20.2kg |

key features

Low Cost - KE-1600's optimized formula reduces the use of high-cost components, maintaining high performance while lowering the cost per mold. Actual application data shows that its average mold life is over 20% longer than that of conventional silicone rubber molds, while the cost per production run is approximately 15% lower.

Specifically designed for polyurethane foam molding - KE-1600 resists sticking when reacting with polyurethane. Test results show that after 500 polyurethane injection cycles, the mold surface remains smooth and crack-free, and the peel force remains consistently less than 0.5 N/mm, ensuring smooth demolding and consistent part surface finish.

Excellent Heat Resistance - KE-1600 maintains a stable heat resistance of 180°C and can withstand temperatures up to 200°C for short periods. In high-temperature polyurethane injection molding tests, the mold showed a hardness change of less than 3% after 100 hours of continuous cycling.

High Hardness - KE-1600 achieves a Shore A hardness of 55-60 after curing, significantly higher than the Shore A of approximately 40 for conventional mold silicones. This high hardness ensures that molds resist deformation under pressure and friction, making it particularly suitable for producing medium to large-volume foam products and demonstrating excellent performance in mold life tests.

Long Mold Life - KE-1600 boasts a tear strength exceeding 25 kN/m and a shrinkage rate below 0.1%, ensuring mold stability even under high-frequency use. Data shows that, under the same conditions, its mold life is an average of 1.5 times longer than that of standard silicone molds, significantly reducing mold replacement frequency and maintenance costs.

Optional Catalyst - KE-1600 offers both fast and slow curing catalysts, allowing users to flexibly select based on process requirements. The fast-curing catalyst allows demolding in 30 minutes at 25°C, while the slow-curing catalyst can extend the curing time to 2 hours, ensuring complete cure for large or complex molds and meeting varying production schedules.

Electronics Industry - KE-1600 demonstrates excellent adaptability in mold manufacturing for the electronics industry. Its high hardness and low shrinkage ensure stability and dimensional accuracy in molds for electronic device housings. In 1,000 repeated molding cycles, mold dimensional variation was less than 0.05%, effectively improving consistency and yield during electronic component production.

Automotive Industry - In automotive parts manufacturing, KE-1600 is commonly used in molds for polyurethane foam interior components, such as seats and armrests. Experimental data shows that the molds remain stable even under high injection temperatures exceeding 150°C, with a hardness drop of less than 5%, ensuring stability in mass production of automotive parts.

Aerospace - The aerospace industry demands extremely high mold precision and durability. KE-1600's low shrinkage and high tear resistance make it ideal for molds for polyurethane composite components. In 200 cycles of hot pressing, mold surface integrity retention exceeded 97%, meeting the demands of this demanding industry.

Industrial Machinery - In the production of mechanical component molds, KE-1600's high Shore A 55-60 hardness and tear resistance ensure that molds retain deformation under high loads over long periods of use. Actual data shows that its mold life is 30% longer than that of ordinary silicone rubber molds, reducing the frequency of production downtime and maintenance.

Home Appliance Industry - Home appliance components, such as polyurethane fillers and sound insulation components, rely on stable mold performance. KE-1600's heat resistance and excellent mold release properties make it suitable for home appliance mold manufacturing. Tests showed that after 500 injection cycles, no cracks or damage were observed on the mold surface, ensuring high production efficiency.

Construction Industry - In the production of building decoration materials, KE-1600 is widely used in polyurethane foam board and decorative component molds. Its long mold life and low shrinkage ensure product dimensional stability. In a 1,000-cycle test, the qualified product rate reached over 98%, significantly improving production reliability and cost-effectiveness.